3-A Standard: Sanitary Requirements According to 3-A Sanitary Standards

What is the 3-A Standard?

The 3-A Standard, officially known as 3-A Sanitary Standards, was developed in the 1920s through collaboration between public health officials, equipment manufacturers, and food processing stakeholders. It was originally intended for the dairy industry but has since been widely adopted across the food, beverage, and pharmaceutical sectors.

Today, 3-A sanitary equipment is crucial in maintaining high hygiene standards in food processing environments. For example, 3-A certified sanitary valves are commonly used in food production, winemaking, and cosmetics manufacturing. These valves, made exclusively from AISI 316L stainless steel, feature a spherical shape and polished internal surfaces to support self-cleaning functionality.

3-A Sanitary Standards Inc. (3-A SSI) is an independent, non-profit American organisation. Over 360 US companies and 22 international firms are authorised to display the 3-A symbol on processing equipment.

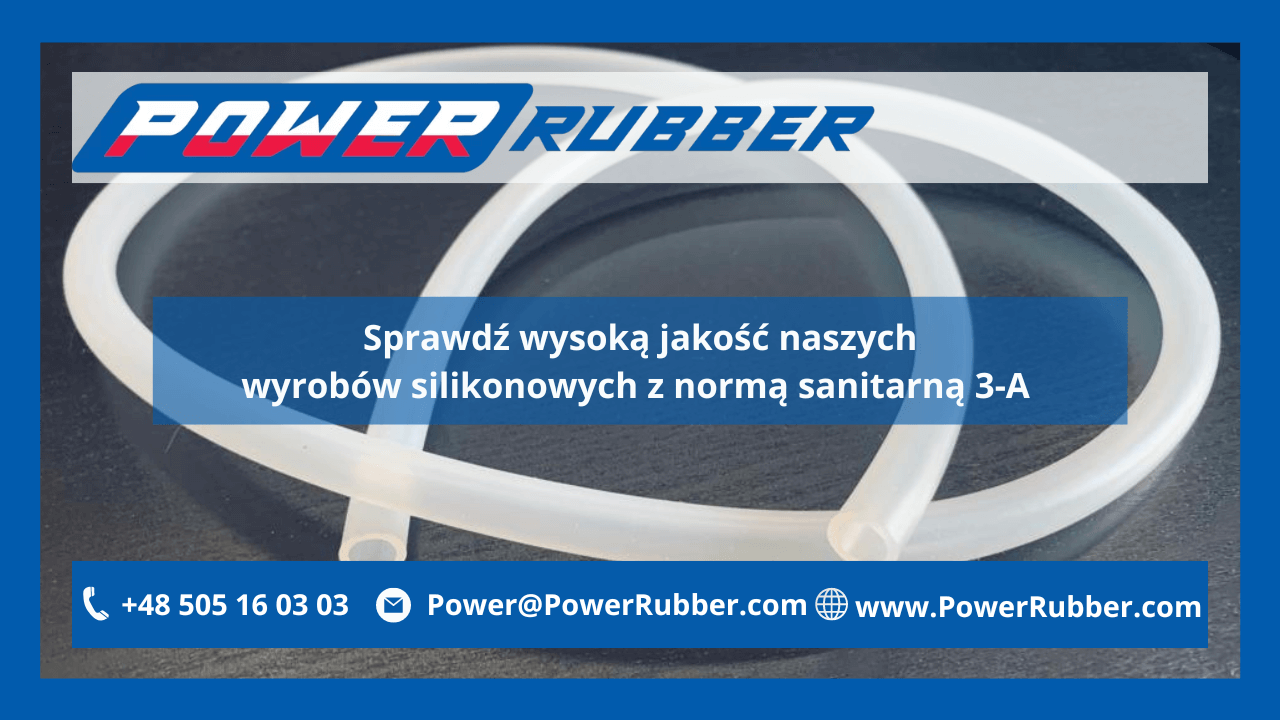

At Power Rubber, we offer high-quality silicone products that meet the 3-A sanitary standard.

Key Objectives of the 3-A Sanitary Standard

-

Improved food safety through hygienic equipment design

-

Contamination prevention of consumable products such as dairy

-

Assurance of cleanability, both mechanical and manual

-

Easy disassembly of surfaces for effective cleaning and inspection

-

Enhanced hygiene in sectors like biotechnology, food processing, beverages, and pharmaceuticals

Food-Grade Silicone Hoses with FDA and 3-A Certification

Whether you operate in the beverage industry, dairy sector, or general food manufacturing, it is essential that all food-contact surfaces are non-toxic, non-absorbent, and corrosion-resistant. According to 3-A hygiene standards, these surfaces must also be smooth, easy to clean, and free of lead or lead-based solder (typically an alloy of lead and tin).

The 3-A certification helps ensure that only compliant products reach the end user. The certificate confirms that specific design and surface finish requirements have been met. There are currently 70 official 3-A sanitary standards and 9 accepted 3-A practices.

3-A vs. EHEDG Certification

The European Hygienic Engineering & Design Group (EHEDG) is a foundation focused on promoting hygienic design practices within the food industry. The EHEDG certificate is widely recognised across Europe.

The main difference between 3-A SSI and EHEDG lies in the certification criteria. While 3-A certification requires equipment to meet detailed design specifications, EHEDG certification also includes mandatory hygienic testing. The 3-A standard tends to provide more specific and technical design guidelines.

Both certifications serve the same ultimate goal: to establish hygienic best practices across the food and pharmaceutical industries, ensuring high standards of cleanliness during production and packaging processes.

At Power Rubber, we stock a wide range of 3-A certified products, including silicone O-rings and food-grade silicone sheets.

Fast Order Fulfilment Guaranteed

If you need more information about our certified products or assistance in choosing the right item, don’t hesitate to contact our team. We provide both paper and electronic invoices.