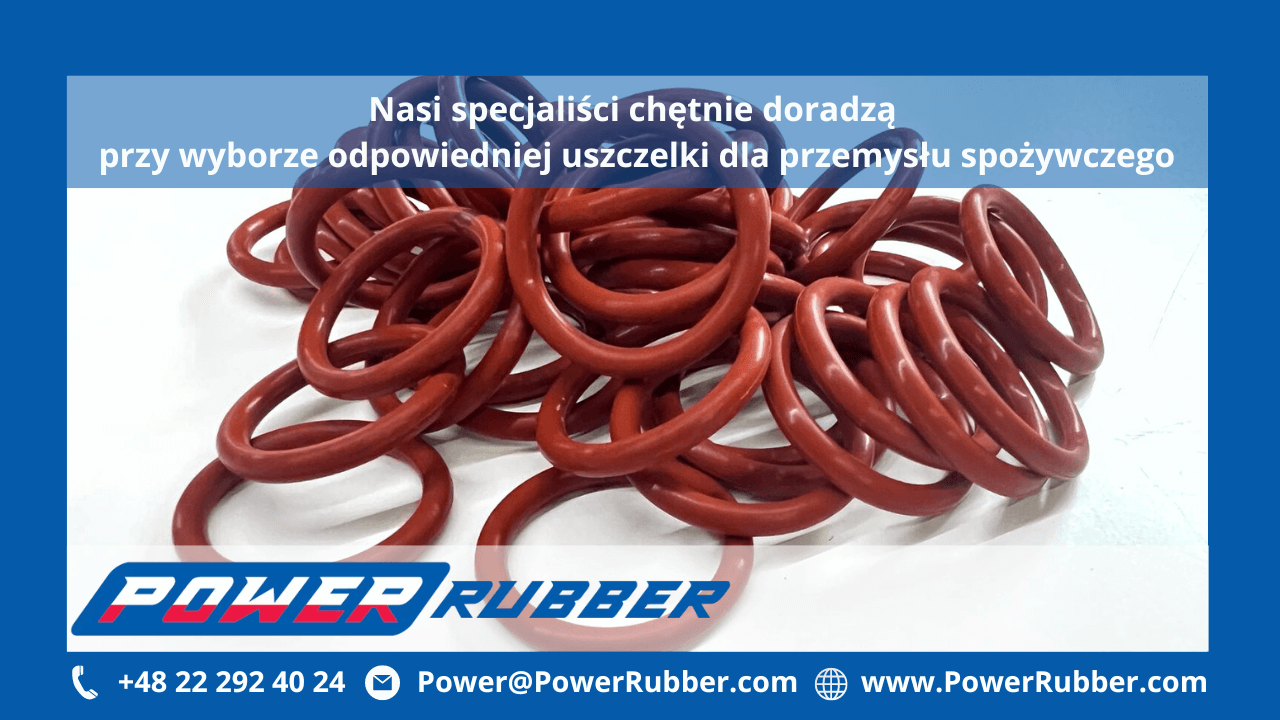

Food Industry Gaskets – What They Are and Why Choose Them?

What are food-grade gaskets?

Rubber gaskets in food processing systems ensure a secure seal between two components, preventing product leaks and contamination. They are made from flexible, food-safe materials and adapt to temperature and chemical exposure without losing integrity.

Why use food-grade seals?

They maintain hygienic conditions, resist extreme temperatures and harsh cleaning agents, and comply with strict safety regulations. They’re essential for reliable, clean, and efficient production lines.

Key features of our gaskets at Power Rubber

We offer seals made from certified materials featuring:

-

High temperature resistance

-

Resistance to cleaning chemicals

-

Compatibility with food and beverages

-

Suitability for fats, oils, acids

-

Strong mechanical performance

Food contact regulations

Compliance with international standards

Materials must comply with EU Regulation 1935/2004 and US FDA regulations. Additional certifications like WRAS, KTW, or PZH are required for contact with drinking water. The 3-A standard is widely adopted in food, cosmetic, and dairy industries.

FDA-certified rubber seals

We offer food-grade rubber gaskets approved for demanding environments, including high temperatures and sterilisation.

Materials used in food-grade gaskets

PTFE (Teflon®)

Highly resistant to chemicals and heat (-200°C to +260°C). Used in mixers, pumps, and dynamic sealing applications.

EPDM

Great for cleaning agents, UV, and ozone. Ideal for dairy and beverage systems, excluding high-fat products.

NBR

Works well with fats and oils, but unsuitable for ozone or steam exposure.

FKM (Viton®)

Excellent chemical and heat resistance. Ideal for fatty foods, alcohol, and intensive cleaning processes.

FFKM

For extreme environments. Withstands nearly all chemicals and thermal exposure.

Silicone

Non-toxic, odorless, flexible, and resistant to microbial growth. Works in both freezing and high-temperature settings.

Differences between hygienic and standard gaskets

Hygienic gaskets don’t absorb liquids, don’t alter food properties, and comply with medical and food safety standards. They ensure safe production and prevent contamination.

Food-grade gasket manufacturer – Power Rubber

Power Rubber provides certified rubber seals for contact with food and drinking water. Our products are widely used in dairy, medical, pharmaceutical, and beverage production.

Contact us at +48 22 292 40 24 or +48 505 16 03 03 – Power@PowerRubber.com