ESD-Resistant PVC Floor Tiles PowerFloor

PowerFloor ESD PVC Tiles – Electrostatic Protection Flooring

PowerFloor interlocking ESD tiles are made from high-quality PVC and engineered for electrostatic discharge-sensitive environments. Stainless steel microfibers are injected during molding, ensuring uniform conductivity throughout the tile’s life – provided it is properly grounded and maintained.

Why choose antistatic PVC flooring?

These ESD PVC tiles create a safe, conductive surface that can serve as the main grounding point in areas requiring static control. Perfect for protecting sensitive equipment and staff. The conductive properties remain effective over time. Available in 6.5 mm thick flexible tiles that withstand forklifts and pallet jacks.

Power Rubber’s ESD flooring is pore-free, hygienic, and easy to maintain – with a grey finish that helps mask dirt.

Easy installation, modular and durable

No glue needed – the modular system allows easy installation and spot repairs. Damaged tiles can be replaced individually. The floor can even be relocated, making it a cost-effective and long-term investment.

PVC mat systems are more affordable than epoxy ESD floors, which lose performance when damaged. The ESD version of PowerFloor meets commercial and industrial durability standards.

Anti-slip surface prevents falls, while the structure provides sound and thermal insulation on cold concrete floors.

Ideal for:

-

Manufacturing plants

-

Laboratories

-

Server rooms and data centers

-

ATEX zones

-

Chemical industry

-

Electrical and electronics sector

-

Pharmaceutical facilities

-

Automotive factories

-

Paper production

-

Rubber industry

Technical Specifications

-

Material: Injection-molded or extruded PVC

-

Metal fiber content: 10%

-

ESD performance: 10^2Ω - 10^6Ω

-

Sizes: 510x510x7 mm (PRO), 653x653x4 mm (MAX)

-

Weight: 2.2 kg (PRO), 2.3 kg (MAX)

-

Hardness: 92±3 Shore A

-

Chemical resistance: high (95% ethanol, oils, acids)

-

Fire rating: Bfl-s1 (EN 13501-1)

-

Slip resistance: R10 (DIN 51130)

-

Wear class: T (EN 660-2)

-

Compression strength: 520 kg/cm3 (EN ISO 604-1)

-

Resistance (R pp): < 10^5Ω (EN 61340-5-1)

-

Ground resistance: < 10^6Ω (EN 61340-5-1)

-

Standards: IPC, IEC 61340-5-1-ESD, ANSI/ESD S541

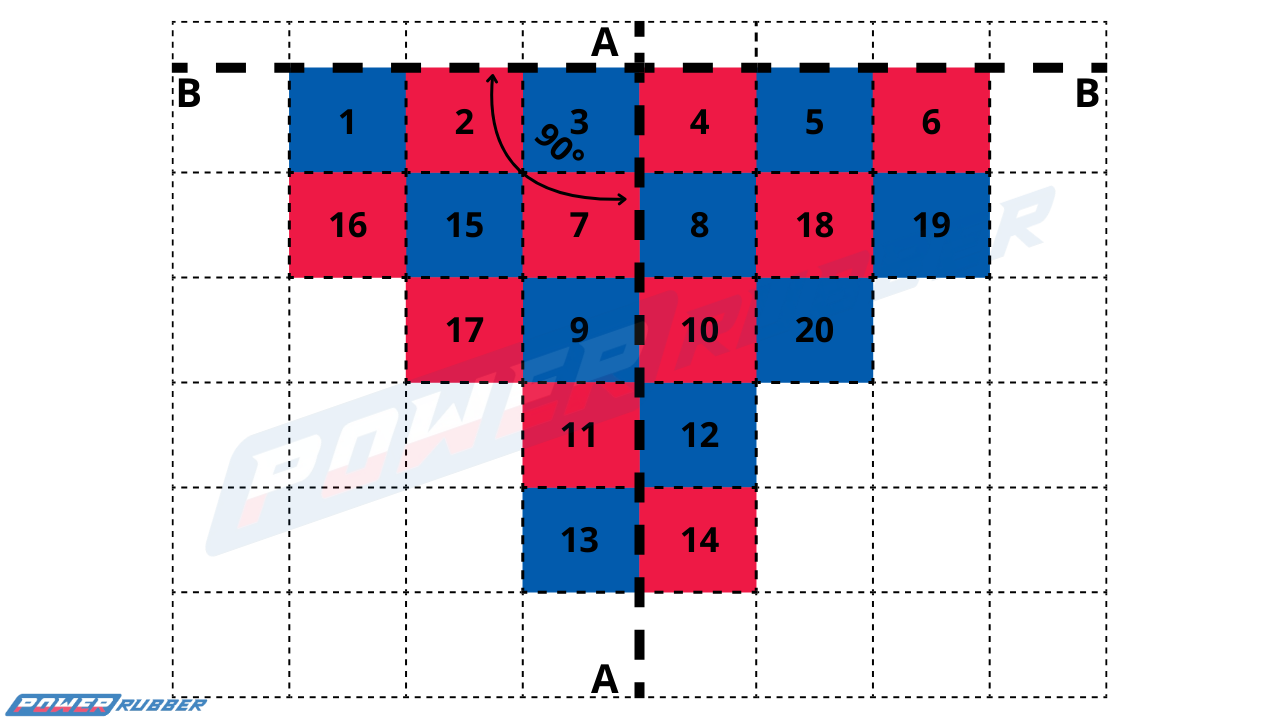

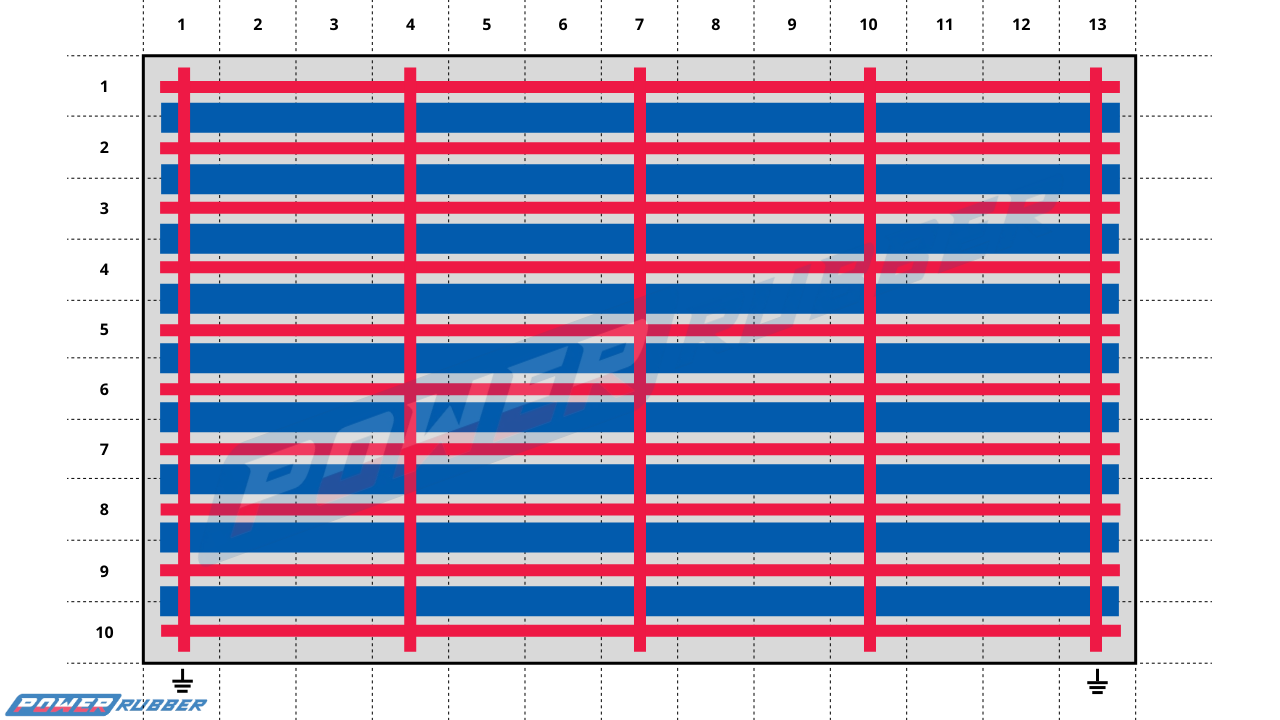

ESD Flooring Installation Guide

-

Prepare subfloor: dry, clean, free of debris or cracks.

-

Measure room.

-

Mark lines A-A and B-B.

-

Grounding: use copper tape + 1MOhm grounding points every 2 m.

-

Tools: rubber mallet, tile cutter.

-

Installation: let tiles acclimatize for 48 h, lay in pyramid shape.

-

Edge finishing: trim tiles, leave 5 mm expansion gap.

-

Cleaning: use antistatic, solvent-free cleaners.

-

Conductivity test: repeat quarterly.

Where to buy ESD PowerFloor tiles?

Available from Power Rubber. Contact our experts at +48 22 292 40 24 / +48 505 16 03 03 or by email at Power@PowerRubber.com