Rubber Seals for Water Applications

Industrial facilities often struggle with leaks caused by damaged technical seals and rubber gaskets, including mechanically worn silicone seals. How to solve this problem? Discover expert advice in the POWER Rubber Guide.

Wide Range of Rubber Seals – Power Rubber’s Offer

At POWER Rubber, we provide a wide selection of rubber gaskets made from various materials and available in multiple sizes. Depending on the compound, these seals offer specific properties such as abrasion resistance, hydraulic fluid and fuel compatibility, or high-pressure durability. They are ideal for a variety of work environments, including water and gas installations.

High-Quality Rubber Gaskets for Peace of Mind

Premium technical seals are essential for long-term reliability and peace of mind. Components of industrial machinery are prone to failure if the right seal is not used. Choosing the correct rubber seal for a specific application ensures prolonged performance and significantly reduces production costs.

Cost Efficiency Through Proper Sealing

As with many things in life, quality comes at a price – but it also brings savings. Investing in high-grade technical seals helps reduce total costs by minimising downtime and increasing efficiency. This is particularly evident in the use of O-rings in manufacturing plants, where a higher unit cost translates into fewer production interruptions.

O-Ring Rubber Seals

When we think of rubber seals, the O-ring is often the first that comes to mind. At POWER Rubber, you can purchase O-rings made from a wide variety of materials. Options include high-temperature silicone O-rings and oil-resistant gaskets. Selecting the proper rubber compound is crucial – natural and synthetic rubbers vary greatly in performance. We recommend consulting with us to ensure your O-rings and seals are tailored for maximum durability.

Fibre Washers for Water Installations

We also offer specialised sealing solutions, such as fibre washers. These gaskets are designed for water contact and expand over time through swelling, filling grooves completely and improving system tightness. Due to their resistance to friction and minor contaminants, fibre washers are commonly used in water meters, radiators, heating systems, pressure gauges, and tap installations.

Klingersil Gaskets – Sealing Sheets

Klingersil sealing sheets are among the most widely used materials for water sealing. They offer excellent water resistance and can withstand up to 7.8 bar and temperatures of up to +200°C. These gaskets are also resistant to common oils and greases like heating oil, making them suitable for various industries, including petrochemical, automotive, and power generation. Their resistance to steam, acids, and alkalis further expands their application. We offer cutting services for Klingersil gaskets in thicknesses ranging from 0.5 mm to 5 mm, and even up to 15 mm with layered sheets.

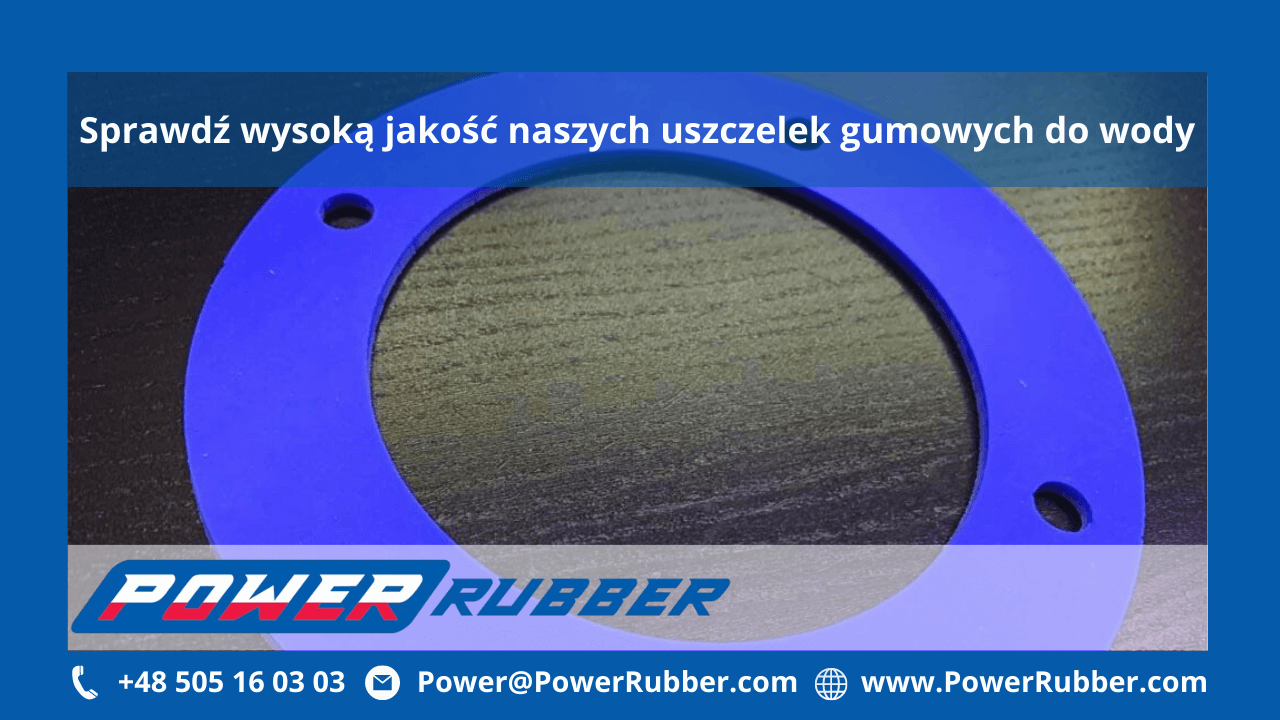

Flange and Flat Gaskets

Flat gaskets for flanges are designed for high-pressure hydraulic or steam systems. They are used to seal connections between components such as pipes. These gaskets can be made from rubber, felt, sealing sheets, cardboard, or thermal insulation paper.

EPDM Rubber Gaskets

EPDM rubber is ideal for water applications. Depending on the formulation, EPDM seals can operate between -40°C and +110°C (sulphur-cured) or up to +177°C (peroxide-cured). EPDM is known for its resistance to steam, ozone, and UV radiation. EPDM O-rings are also widely used in air conditioning systems, supporting leak-proof operation and environmental protection.

Silicone Rubber Seals

Different types of rubber are suited to specific uses. Silicone rubber is ideal for high-temperature environments, tolerating up to +300°C. Silicone seals are frequently used in the food industry due to their compliance with FDA standards, ensuring safe contact with drinking water and food. Silicone rubber is also used in medical and pharmaceutical applications. Products are manufactured from VQM or MVQ compounds and include custom-moulded parts upon client request.

Silicone’s resistance to fresh and saltwater, combined with FDA certification, makes it a reliable material for potable water seals.

For any questions, please contact us at +48 222 924 024 or +48 505 16 03 03, by email at Power@PowerRubber.com, or via our contact form.