Rubber Wheel Chocks for Aircraft

Rubber aircraft wheel chocks are a standard piece of equipment at every airport. Placed in front of or behind the wheels, they allow airplanes to be stopped in a designated place. They prevent unwanted movement of flying units during parking or maintenance. They increase safety and improve the movement of aircraft.

If you want to know how you can reduce the number of injuries to ground handling personnel and ensure the safety of bystanders, read the article below.

Why are aircraft wheel chocks so important?

Rubber chocks are used in civil, commercial, and military aviation. Tire blocks reduce the risk of hazards and prevent accidents and collisions during parking on the apron or in the hangar. Their use ensures life protection!

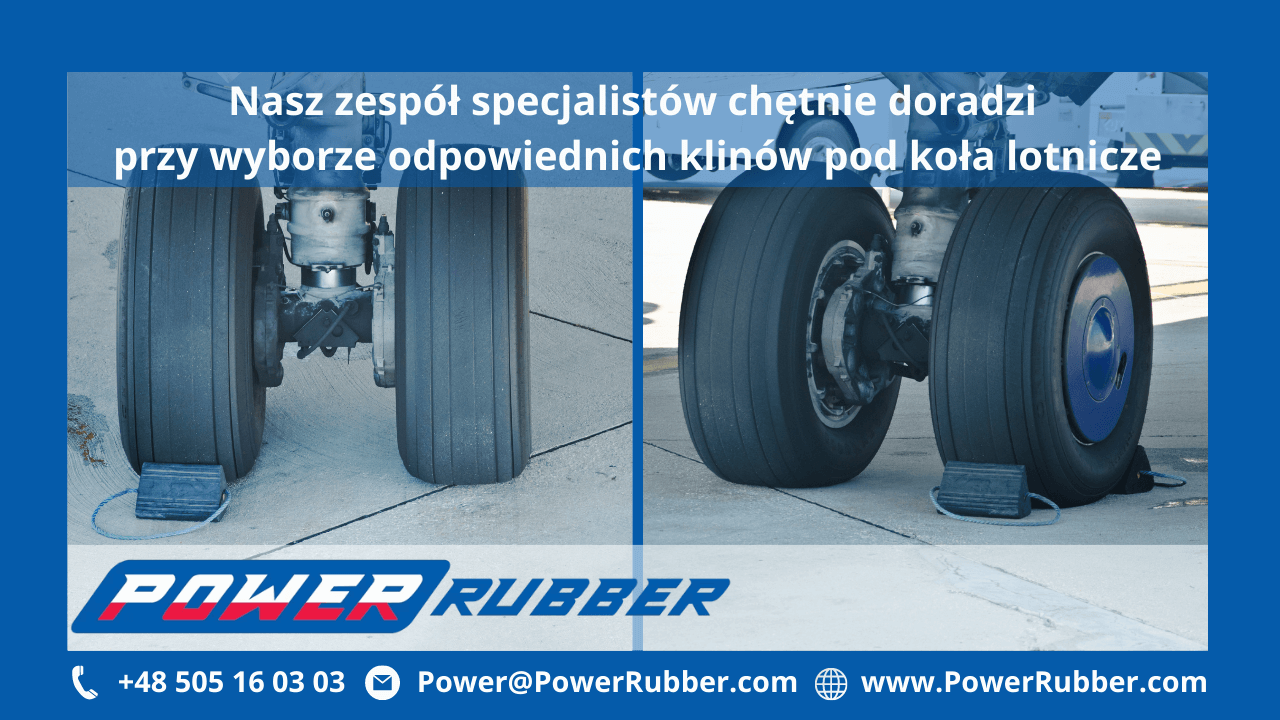

Wheel chocks are placed on both sides of the aircraft after it has stopped and the brake is engaged, to prevent it from moving during parking, refueling, or maintenance. They conform to the shape of the tires and also have a special grooved surface that increases grip. They are ideal for smaller private planes and large passenger aircraft.

The blocks differ in weight depending on their size. They are sold individually with a rope or connected in pairs. Simple installation by blocking the wheel or wheels shortens service time (requires no additional tools). Variants equipped with ropes further increase safety.

To effectively block the wheels, the chock must be selected according to the tire size and the vehicle's mass (working load limit) with and without load.

Rubber wheel chocks - products available in our store

What are aircraft wheel chocks made of?

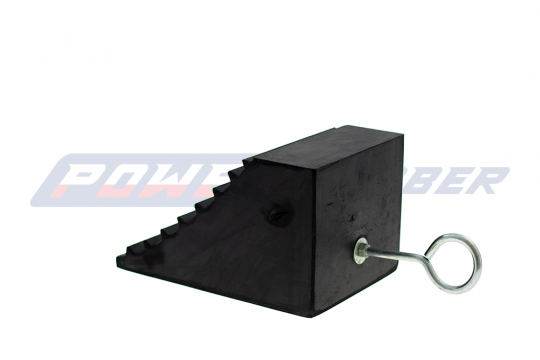

Wheel chocks were originally made of various materials (wood, steel). At Power Rubber, the production of wheel chocks is made from a high-quality, high-density rubber compound with a triangular design. The triangular design is used in the aviation industry worldwide.

Shape of Wheel Chocks – Increase Safety

The shape of aircraft wheel chocks is designed to distribute the forces resulting from a moving airplane or aircraft. The forces after chocking will cause a change in direction to the opposite, i.e., changed by 180°, to ultimately stop the unit in the right place. Profiled, beveled edges ensure optimal friction with the ground.

airplane wheel chock

airplane wheel chock

What are the benefits of placing Power Rubber chocks under the wheels?

Every user of a truck or passenger car should know how important safety is during parking. The use of high-quality rubber tire chocks guarantees durability, resistance to a wide range of temperatures and damage, and resistance to degradation from UV radiation.

Using durable and technically sound chocks is an economical solution that saves money in the long run. The products we offer are resistant to environmental conditions, aviation fuel, oils, and greases. They do not crack or crumble during use.

Some models have reflective markings that improve visibility, as well as special handles (ropes) visible in the photos, which allow for efficient removal of the chocks and easy transport.

Our chocks were created with a variety of applications in mind. They provide durability and reliability. They are also perfect for mining, construction, as well as when parking a vehicle on a steep slope, in a garage, during loading and unloading of goods, etc. You will find all data and specifications in the product description.

Manufacturer of Rubber Chocks – POWER Rubber

We invite you to take advantage of our offer for a wide range of rubber products manufactured at POWER Rubber, including rubber aircraft wheel chocks.

For more information, please contact us by phone or via the contact form.