How to Reduce Vibrations, Noise and Shocks

Impacts, noise and vibrations negatively affect the proper operation, durability of machines and their components, as well as the health of operators.

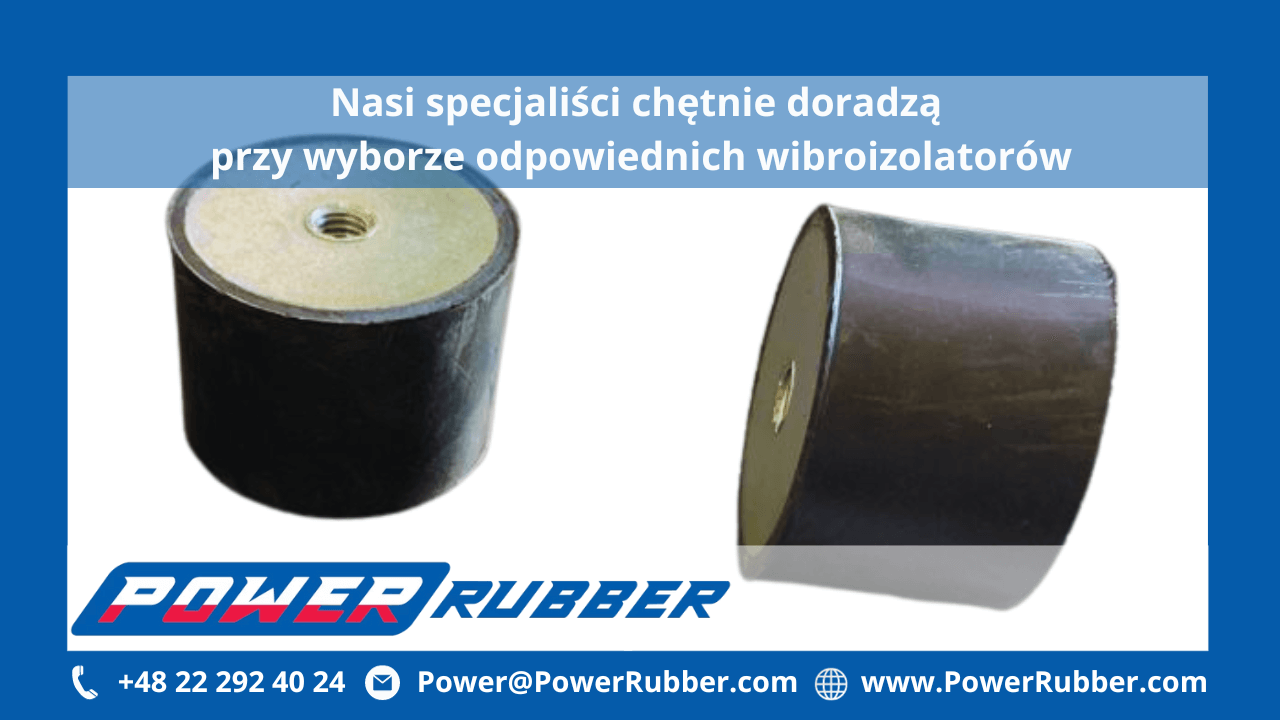

Anti‑vibration mounts are specialised dampening elements designed to absorb shocks and vibrations. They’re mounted between the machine base and the floor.

Implementing vibration isolation measures is key. Power Rubber anti‑vibration mounts reduce vibration damage, protect mechanical systems from wear, prolong machine lifespan, and ensure trouble‑free performance. They also significantly lower noise emissions.

Power Rubber Vibration Isolation Solutions

We offer a broad range of anti‑vibration mounts engineered for high vibration dampening—capable of withstanding compression, shear, or combined loads.

Made from rubber or rubber‑metal combinations (e.g. galvanised steel with various rubber compounds). Available in multiple sizes, M‑thread types, and with varied widths, lengths, hole depths and stud lengths.

Benefits of Choosing Power Rubber

-

Protects machines and parts from excessive wear — extended service life

-

Reduces industrial noise levels

-

Isolates sensitive components from harmful vibrations

-

Effectively absorbs shocks and vibrations, preventing mechanical damage

Types of Anti‑Vibration Mounts

-

Cylindrical mounts

-

Flanged mounts

-

Disc mounts

-

Tapered mounts

-

Parabolic mounts

-

With or without protective caps

-

Steel alloy and stainless steel models

-

Also available: rubber-cord and spring mounts

Mounting Anti‑Vibration Pads

Depending on the type, install via through-threaded holes. Insert the mount into the machine base, level by turning the stud clockwise, then tighten the securing nut. Do not install by twisting the mount itself.

Rubber‑Metal Vibration Mount Types (A–E)

We produce five standard types:

-

Type A: two external threaded studs (male–male)

-

Type B: one threaded stud and one threaded hole (male–female)

-

Type C: two threaded holes (female–female)

-

Type D: one stud with a flat base (male–flat)

-

Type E: one threaded hole with a flat base (female–flat)

Each type suits different operating conditions, temperatures and mounting needs. Their design ensures rigidity under dynamic loads and efficient vibration absorption.

Industrial Applications

Used widely for vibration isolation of motors, gearboxes, shafts, suspensions, compressors, pumps, fans, machine tools, audio systems, measurement equipment.

Proper selection, even load distribution and mounting ensure optimal machine efficiency and reduced vibrations.

Expertise at Power Rubber

We provide tailored consulting on vibration mounts based on machine type, base thickness, hole patterns, total weight, natural frequency, and working environment.

Safe Mounting Solutions

Secure tailoring of machines to the floor via mounting holes. Choose Power Rubber anti‑vibration mounts to effectively eliminate vibration and noise!

Explore also our other rubber products: Crossfit discs, mats, gasket sheets, cords, O-rings and more.

Contact us: +48 22 292 40 24 or +48 50 516 03 03 | Power@PowerRubber.com | via our contact form.