Maty gumowe dla stanowisk spawalniczych

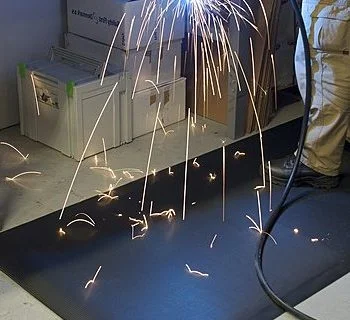

Maty spawalnicze to ognioodporne maty gumowe przeznaczone dla przemysłowych stanowisk spawalniczych. Chronią przed iskrami i gorącymi gazami spawalniczymi, zapewniając przy tym antypoślizgowość i komfort użytkowania.

Właściwości mat gumowych

Kluczową cechą jest ognioodporność — maty wytrzymują iskry oraz wysoką temperaturę spawania. Wykonane z wysokiej jakości gumy, mają warstwę wierzchnią PVC o chropowatej strukturze oraz piankowe podłoże, co zapewnia ochronę przed zmęczeniem. Pasują do temperatur od 0 °C do 40–60 °C. Są odporne na ścieranie, łatwe w czyszczeniu i dzięki czarnej barwie estetyczne w użyciu. Fazowane krawędzie zmniejszają ryzyko potknięcia.

Format i dostępność

Maty spawalnicze dostępne są w formatach takich jak 60×90 cm, 90×150 cm, 90×183 cm — jako gotowe płyty, na rolce lub przycinane pod wymiar.

Zastosowanie

Idealne do zakładów przemysłowych, stanowisk spawalniczych i ślusarskich. Właściwości antyzmęczeniowe zwiększają bezpieczeństwo i komfort pracy.

Gdzie kupić?

Maty do spawalnictwa można zakupić w sklepach stacjonarnych lub online. Dostępna jest opcja cięcia na wymiar, a termin dostawy i koszty wysyłki zależą od wielkości i wagi.