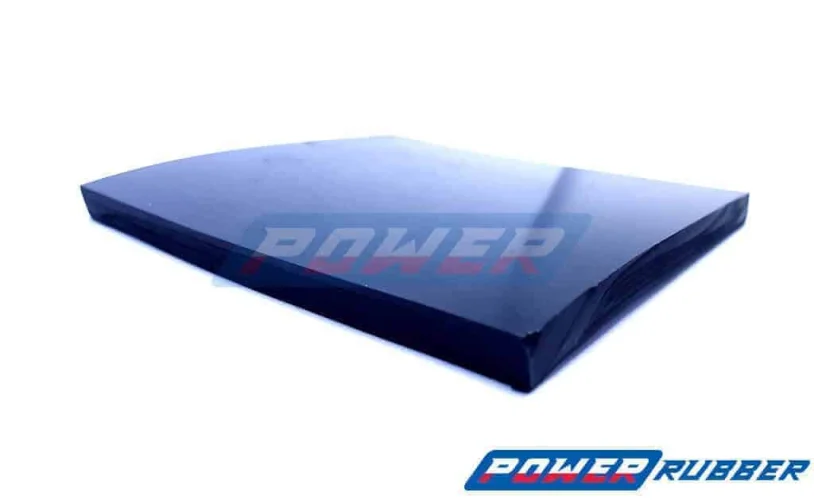

Rubber plates are protection for multi-kilogram machines and devices. They are made of solid rubber, which is characterized by high strength and neutralize the negative effects of the devices. They will work wherever heavy equipment is used, especially if it is used by employees. Rubber plates for machines improve safety and improve productivity and comfort for workers.

Types of rubber plates for machines and equipment

Rubber primers are a product that has many variants. You can decide m.in. e.g. rubber mats with thicknesses of 3, 4, 5, 8, 10 mm or more are available up to 50 mm. There is also a wide range of plate dimensions. Looking for a product for yourself, you can come across companies encouraging with the slogan:" Rubber plates for machines wecut", which cutrubber mats at the customer's request. Thanks to the exact fit to the machine, the rubber mat will fit perfectly into the surface on which it will be located. Production to size is a service offered by any company that cares about the needs of customers. Among the rubber plates are distinguished several types: SBR boards - general use, NBR - oil-resistant and EPDM - weather-resistant and ozone resistant. SBR boards are the most versatile, but not resistant to more difficult conditions, they are used under standard conditions. NBR boards are recommended to be installed where various types of oils, lubricants, oil or petroleum substances are used. EPDM boards, on the other hand, are resistant to weather conditions, ozone and UV rays, so they can be used outdoors. You can also opt for rubber mats for machines reinforced individually, with two spacers or even three spacers. Use of rubber plates for machines

Rubber sleepers are useful in any industrial plant where machines are located. They protect equipment and floor from damage and increase the safety of people in the vicinity of machines. The plate should be selected taking into account the weight and size of the devices. The heavier ones require thicker sleepers to effectively protect the substrate and the people operating the equipment. Temperature resistance may also be important in the selection. Epdm mats are the most resistant and can be used at temperatures from -40 st. up to 100 st. Celsius. The other types of mats have a slightly lower strength, because from -30 st. up to 70-80 st. Celsius. Why are rubber sleepers needed?

Rubber plates placed under heavy equipment make their use less cumbersome. The rubber plate damming the vibrations caused by the working machine and reduces the noise produced by it. At the same time, it protects the floor from damage caused by the work of machines. It prevents them from moving on the floor of devices that vibrate, reposition and cause ground abrasions. In addition, the rubber mat has insulating properties, which is important in the event of a failure of the device when there is a risk of electric shock. The primer made of rubber does not conduct current, so it protects the worker from paralysis. Rubber plates - the most important properties

A big advantage of the plates is their anti-vibration property - rubber mats under the machines dampen the vibrations produced by them. Depending on the type of material, rubber plates can be resistant to oils or weather conditions and ozone. If the working conditions are not particularly difficult, sbr rubber plates can be used, which prevent slipping of machines and people. What's more, the rubber mats under the machines are insulators, so they protect against electric shock in the event of a machine failure. Thanks to the high abrasion resistance, the rubber plate is able to withstand heavy loads, so any production plant, workshop, hall where numerous tools are used should be equipped with rubber sleepers. SBR or NBR reinforced rubber plates are recommended for harsh operating conditions. Not the most important, but the characteristic that affects the use of the mat is the smell. Products made of good materials do not give off an unpleasant odor that could negatively affect the person working near the mat. How much do rubber plates cost for machines and equipment?

To please the customer, we offer a wide range of products. However, this involves a price set individually, which depends on the customer's requirements. The rubber plate can also be cut into meters or sold in the entire roll or in sheets. The price depends on the size, thickness and whether reinforced rubber plates are ordered or without reinforcements.