Niepalne maty gumowe do stanowisk spawalniczych

Maty gumowe do spawalni – ochrona przed ogniem i wysoka odporność termiczna

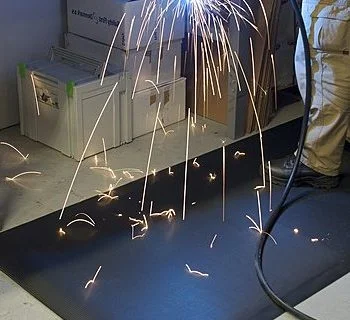

Maty gumowe do stanowisk spawalniczych to niezbędny element wyposażenia każdej spawalni oraz miejsc narażonych na działanie wysokiej temperatury lub ryzyko pożaru. Ich głównym zadaniem jest ochrona podłoża i pracowników przed działaniem iskier, gorących odprysków czy płomieni. Wykonane z wysokiej jakości mieszanki gumowej, zapewniają trwałość, bezpieczeństwo i komfort pracy.

Właściwości mat gumowych do spawania

Maty te cechują się:

-

odpornością na ogień i temperaturę do 95°C,

-

antypoślizgową powierzchnią,

-

właściwościami antyzmęczeniowymi – zmniejszają zmęczenie nóg podczas pracy na stojąco,

-

wytrzymałością na rozdarcia, ścieranie i zginanie.

Wiele modeli posiada konstrukcję dwuwarstwową: wierzch odporny na ogień, spód amortyzujący i antypoślizgowy.

Parametry techniczne mat przemysłowych

Maty gumowe dostępne są w różnych rozmiarach – jako moduły, rolki lub na wymiar. Typowa grubość to 15–17 mm, a twardość ok. 65 ShA. W składzie często znajduje się nitryl, który zwiększa odporność chemiczną i cieplną. Zakres temperatur użytkowych to od -35°C do +95°C.

Zastosowanie mat gumowych do stanowisk spawalniczych

Tego typu maty znajdują zastosowanie nie tylko w spawalniach, ale też w:

-

hutach,

-

kopalniach,

-

zakładach przemysłowych,

-

warsztatach mechanicznych.

Maty mogą być układane na podłogach lub blatach roboczych – w zależności od potrzeb.

Największe zalety mat trudnozapalnych

-

Niepalność: idealna ochrona przed iskrami i ogniem,

-

Antypoślizgowość: zwiększa bezpieczeństwo pracy,

-

Mobilność: łatwe do przenoszenia i układania bez kleju czy montażu,

-

Bezpieczeństwo krawędzi: fazowane brzegi zapobiegają potknięciom.

Cena i dostępność

Maty gumowe można kupić w sklepach budowlanych oraz online. Wersje online często są tańsze i dostępne w szerszej gamie rozmiarów. Cena zależy od grubości, rodzaju gumy, formatu i ewentualnego docinania na wymiar.