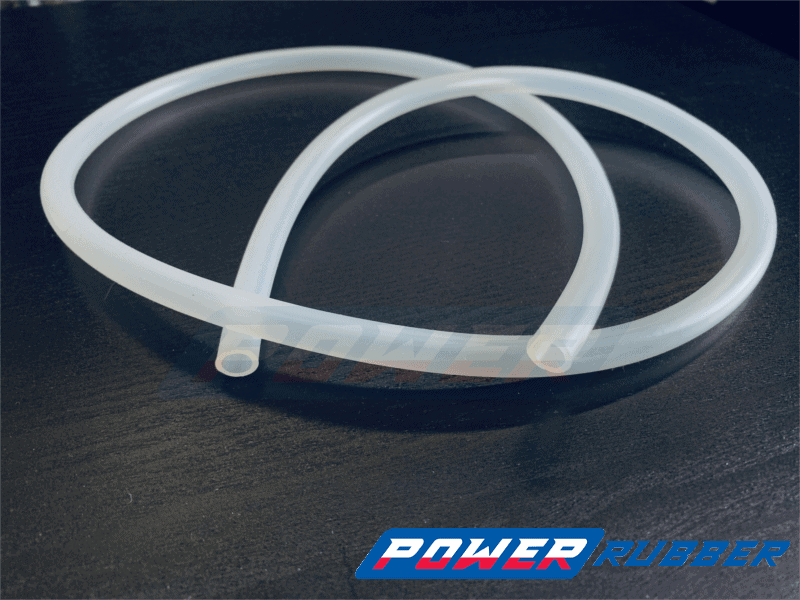

Rubber hoses

08.03.2021

Rubber hoses are often used in everyday life. A wide range of different rubber hoses made of different materials are available on the market. This variety makes this type of product suitable for many applications.  You can find the full range of rubber hoses here Safety information Different categories of rubber hoses, regardless of use, should be regularly checked and tested. It is recommended to check the condition of the hose and fittings each time before use, in particular when they come into contact with hazardous chemicals. Contact with chemicals can be dangerous, so choose a rubber hose designed to transfer this type of liquid. Before use, make sure that the hose has no cuts, cracks, abrasions, blisters. In addition, in our shop you will also find rubber hoses for cars - for fuels and oils, for cooling system as well as hoses for gas installation, welding hoses - Welcome to the PowerRUBBER store or contact below

You can find the full range of rubber hoses here Safety information Different categories of rubber hoses, regardless of use, should be regularly checked and tested. It is recommended to check the condition of the hose and fittings each time before use, in particular when they come into contact with hazardous chemicals. Contact with chemicals can be dangerous, so choose a rubber hose designed to transfer this type of liquid. Before use, make sure that the hose has no cuts, cracks, abrasions, blisters. In addition, in our shop you will also find rubber hoses for cars - for fuels and oils, for cooling system as well as hoses for gas installation, welding hoses - Welcome to the PowerRUBBER store or contact below

What to look for when choosing a rubber hose?

Inner diameter of rubber hose Choose a rubber hose with an inner diameter that will allow fluids to flow freely inside. A hose with too small a diameter can lead to a drop in pressure inside the hose and consequently reduce the speed and efficiency of the flow of the working fluid. Pressure losses also occur during the flow of the m.in. elbows, valves or other constrications. Rubber hoses with a small internal diameter increase the flow rate of the liquid and can significantly increase the working pressure. Large diameter rubber hoses make the flow rate inside low and thus low operating pressure possible. The dimensions of the rubber hose are related to the inner diameter (ID), the outside diameter (OD), and the wall thickness (WT). Temperature and surroundings If there is a high or low temperature in the working environment in which the rubber hose is used, then its parameters should be appropriately selected for the prevailing conditions. A high temperature of a liquid that exceeds the technical parameters of an industrial hose can cause deformation, damage, reduced service life or leakage of the medium. A rubber hose, the technical parameters of which are not adapted to the temperature of the flowing liquid, negatively affect its mechanical properties. Depending on the rubber mixture from which the rubber hose is made, it can be used for continuous operation within the temperature range specified by the manufacturer. If the technical parameters are not designed for low temperatures, the rubber hose becomes less flexible and therefore more prone to cracking and crushing. The action of ozone (also emitted during electric welding) or strong UV radiation can contribute to the degradation of such products. There is a risk that due to the influence of the environment, the outer shell of the rubber hose loses its elasticity and can break in sensitive places that are directly exposed to unfavorable factors. Permissible pressure When selecting rubber hoses, its operating conditions must be determined, including the maximum operating pressure, which shall be the same or greater than the maximum operating pressure of the hydraulic system. All information regarding the maximum operating pressure shall be provided by the manufacturer. Medium The inner rubber layer has direct contact with the flowing medium. Depending on the type of medium (hot water, oils, fuel, gas), both the inner and outer layers, the pipe connector and the gasket must be compatible with each other and be resistant to its operation. Choose such a rubber hose, which in contact with the medium will not cause any chemical reaction. Connectors for connectors Choose rubber hose fittings that guarantee adequate tightness, thereby preventing leakage of the working fluid. Apply An important issue in the choice of rubber hose is its purpose. Many different products on the market allow you to choose the right rubber hose according to demand (application options vary). It is worth noting under what conditions the hose will be used and what fluids will flow through it. Industrial hoses, depending on the parameters, will find application in the gas system, the flow of hot water, steam, fuels.Storage of rubber hoses

Rubber hoses are subject to aging. In order to extend service life, such products should be stored properly. Improperly stored industrial hoses can lose their flexibility and become more fragile and vulnerable to damage. Improper storage and misuse causes rubber hoses to lose their physical properties, i.e. the use of rubber hoses. deformation, cracking, softening. Storage environment and temperature Industrial hoses should be stored in a dry, cool, moderately ventilated room away from ultraviolet and radioactive materials. The relative humidity of the air at the storage site should be below 65%. Condensation should also not be allowed. Such rubber products, due to the direct action of sunlight, should not be stored outdoors. Rubber hoses should be protected from drafts using m.in. special tarpaulins. Depending on the type of products and elastomers needed to make it, the storage temperature should not be less than -10° C and higher than +15° C (short-term maximum to +25°C). During the heating season, industrial hoses should be stored away from the heat source (minimum 1 m). Avoid contact with chemical corrosive substances, disinfectants, lubricants. Also ozone has a negative effect on the service life of rubber hoses. They should be stored away from the site of welding work, during which there is a heavy ozone load. In order to avoid de-layering, deformation or damage to surfaces, they must be protected against m.in. oxygen, moisture, solvents, ozone, heat, UV radiation and strong artificial light with ultraviolet. There are two options that are used to protect rubber hoses from light: the use of curtains or screens in red or orange. In the room it is recommended to use ordinary light bulbs.Types of rubber hoses – Examples

Rubber hoses are an integral part of many industries (agriculture, mines, construction, factories) that have their own distinctive needs and requirements. The type of rubber hose should be appropriately selected according to specific needs (type of material, size of internal diameter, flow temperature, application). Rubber hoses are used to transmit various types of liquids (steam, fuel, oil, gas, food, air), so choose the material from which they are made for its intended purpose. Improperly selected technical parameters of this type of products can affect the safety of use. Rubber hoses can be divided into different categories, depending on the purpose. Rubber hoses for hot water Hot water hoses are also available on the market. They are designed in such a way as to keep their properties in contact with high temperature water (up to 125 ° C). The hot water rubber hose is characterized by high burst strength, thanks to which it is used not only in industry, but also in domestic applications. Many products that are available on sale provide high quality, do not deform, and retain their physical strength and flexibility at high water temperatures. The water rubber hose also has technical parameters that show resistance to weather conditions, ozone, water, different temperature range. Information on working in a specific temperature range is provided by the manufacturer. Rubber hose for drinking water The drinking water rubber hose should meet the standards that allow it to come into contact with food products or semi-finished products. For food contact, select a rubber hose whose materials comply with applicable Food Contact Materials (FCM) regulations. Rubber hose for drinking water or food substances (juices, oils, alcohols) is free of taste and smell, and does not contain harmful substances (dyes, fillers). Steam rubber hoses Available steam rubber hoses are most often made of synthetic rubber and reinforced with steel wire. There are various application options for this type of products: steam cleaning, steam pumps, heat control, fire prevention, chemical plants, industrial heating steam installations. They allow water vapour to flow at temperatures reaching more than 160 °C safely, with a maximum operating pressure of 6 to 18 bar. Compressed air hoses Various categories of rubber hoses with specific technical characteristics are available for sale. Rubber hoses for compressed air are resistant to adverse weather conditions, resistant to abrasion and bending. Pneumatic tools are often used, which require compressed air transfer for operation. Reinforced rubber hose The reinforced rubber hose is equipped with a spiral made of plastic or steel. It has various application options: transport of hard-abrasive materials (quartz sand, mineral wool, plastic pellets, sand, cement), transport of food materials (sugar, cereals). The reinforced rubber hose most often performs a suily-discharge function. An abrasive hose (reinforced rubber hose) is also recommended where electrostatic charges accumulate (e.g. in tanks). Such products, thanks to copper wires inside the rubber, have antistatic properties, which are responsible for the discharge of electrical charges. You can find the full range of rubber hoses here Safety information Different categories of rubber hoses, regardless of use, should be regularly checked and tested. It is recommended to check the condition of the hose and fittings each time before use, in particular when they come into contact with hazardous chemicals. Contact with chemicals can be dangerous, so choose a rubber hose designed to transfer this type of liquid. Before use, make sure that the hose has no cuts, cracks, abrasions, blisters. In addition, in our shop you will also find rubber hoses for cars - for fuels and oils, for cooling system as well as hoses for gas installation, welding hoses - Welcome to the PowerRUBBER store or contact below

You can find the full range of rubber hoses here Safety information Different categories of rubber hoses, regardless of use, should be regularly checked and tested. It is recommended to check the condition of the hose and fittings each time before use, in particular when they come into contact with hazardous chemicals. Contact with chemicals can be dangerous, so choose a rubber hose designed to transfer this type of liquid. Before use, make sure that the hose has no cuts, cracks, abrasions, blisters. In addition, in our shop you will also find rubber hoses for cars - for fuels and oils, for cooling system as well as hoses for gas installation, welding hoses - Welcome to the PowerRUBBER store or contact below