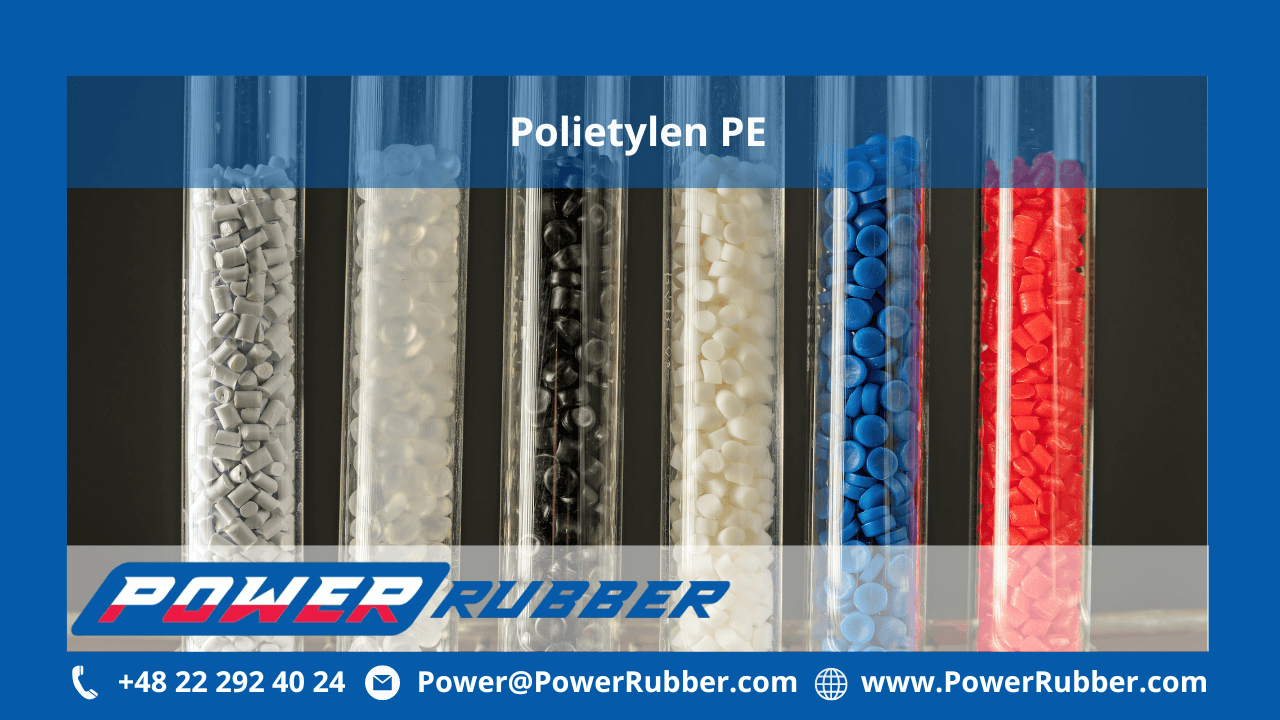

Polyethylene PE500 vs PE1000 – What’s the Difference?

What is Polyethylene (PE)?

Polyethylene is a lightweight, durable thermoplastic polymer made from the polymerisation of ethylene gas. It’s chemically inert and non-polar. Classified by density and molecular weight, PE can be processed via injection moulding, extrusion, thermoforming, welding or laser cutting.

Key Properties of Polyethylene

-

Excellent chemical resistance

-

Low friction and good sliding properties

-

Low electrical conductivity

-

Dimensional stability

-

Water resistance

-

High impact strength

-

Food-safe (FDA-approved)

-

High abrasion resistance

-

High tensile strength

-

Flexible and easy to machine

Types of PE

-

LDPE (Low Density)

-

HDPE (High Density)

-

UHMWPE (Ultra High Molecular Weight)

PE Grades

PE300 (HDPE): Low molecular weight, soft, used in construction and chemical containers.

PE500 (HMWPE): Medium molecular weight, excellent chemical resistance, low moisture absorption. Widely used in food processing.

PE1000 (UHMWPE): Extremely long chains, superior wear resistance, low friction, performs at -200°C.

Key Differences: PE500 vs PE1000

PE500

Cost-effective for moderate applications, good chemical resistance, sound-dampening properties. Slightly harder, less wear-resistant.

PE1000

Top-grade HDPE with ultra-high molecular weight, extreme durability, best sliding performance, lowest friction coefficient.

Summary

-

Molecular weight: PE1000 > PE500

-

Wear resistance: PE1000 better

-

Impact resistance: PE1000 superior

-

Friction: PE1000 lowest

-

Temperature range: PE500 = -100°C to +80°C, PE1000 = -200°C to +100°C

Applications for PE500 and PE1000

PE500

Ideal for food, agriculture, mechanical and conveyor industries:

-

Cutting boards

-

Worktops

-

Guide rails

-

Bushings

PE1000

Used in heavy-duty environments, chemical and packaging industries:

-

Conveyor components

-

Bottling lines

-

Storage systems

-

Sliding pads, seals, rollers

Where to buy PE500 & PE1000?

At POWER Rubber, we offer high-quality polyethylene for industrial and engineering applications. Contact us for expert advice or a free quote:

-

Phone: +48 22 292 40 24 or +48 505 16 03 03

-

Email: Power@PowerRubber.com