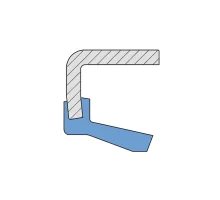

Oil seal

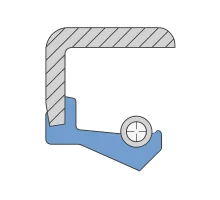

High-speed shaft seals - Simmerings

Simmerings are technical seals used in rotating shafts that prevent oil and grease leaks and protect mechanisms from contaminants. They consist of an elastomeric sealing lip, a compression spring, and often a metal reinforcement, ensuring their durability. Thanks to various design variants, they are used in automotive, machinery, and hydraulic industries.

Simmerings - Purpose

The main purpose of using simmerings is to protect internal components from contaminants (dirt, dust, or mud). Additionally, they increase the ability to store lubricants inside the seal. Both applications contribute to the increased lifespan of individual components in which they are used.

Simmerings Catalog

The place where you will find a list of available technical seals is the simmerings catalog, which features advanced technical seals available in many models. Currently, there are many designations on the market, so we invite you to contact us, and we will assist you in selecting the right seal.

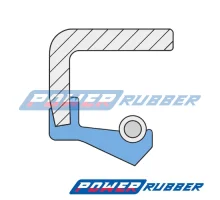

Shaft oil seals types: A AH AOH AO AD AOD AE AF AOF AN

Wide range of sealing rings for rotating shafts also available from us. Feel free to contact us for details regarding orders of:

- sealing rings A

- sealing rings AH

- sealing rings AOH

- sealing rings AO

- sealing rings AD

- sealing rings AOD

- sealing rings AE

- sealing rings AF

- sealing rings AOF

- sealing rings AN

Seals Catalog available via email contact.

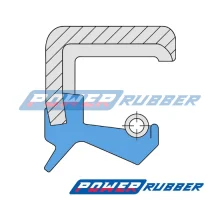

Rotary shaft seals

Our clients often inquire about the applications of technical seals for rotary motion. In most cases, we recommend considering the simerings offer. Their main purpose is to control the tightness of high-pressure systems. These seals protect and secure against oil leaks, lubricants, and other lubricating substances. An example of their application is in car gearboxes and drive shafts, where specific sealing rings designed for rotary motion are visible.

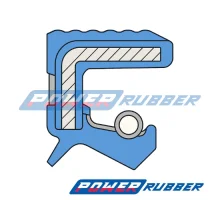

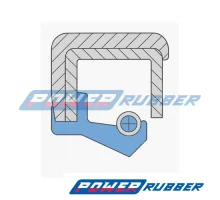

Dual-lip seals

One of the most common types of oil seals are double-lip oil seals. Double-lip oil seals are shaft seals equipped with two sealing lips - a main lip that prevents oil and grease leaks, and an additional dust lip that protects the mechanism from dust and dirt. Thanks to this design, they provide better sealing and longer lifespan in demanding operating conditions. They are used in engines, gearboxes, hydraulic pumps, and transmissions, where protection against external factors is crucial.

Double-lip seals - Application

The use of this type of seals with an additional lip is very common. It is most often seen in places where there are large amounts of contaminants. What function does the additional lip perform? The additional lip protects against dust, dirt, and debris. At the same time, it allows for use in systems with increased pressure.

Rotary seals

Rotary seals are components that prevent leaks of oil, grease, and other fluids in mechanisms with rotating shafts relative to the housing. Rotary seals allow for the protection of rotating elements. Examples include shafts and crankshafts. Their purpose is also to protect the system from contaminants such as dust, moisture, or dirt. They are used in engines, gearboxes, pumps, and industrial machinery, where sealing integrity and reliability under harsh operating conditions are crucial. Feel free to check out our wide range of technical sealing solutions.