Certified Rubber Hoses for Milking Machines

The dairy industry, a sector within the food industry, focuses on the production and distribution of milk and various by-products such as cheese, buttermilk, butter, kefir, yogurt, and cream. This sector is currently rapidly growing and requires increasingly advanced equipment to efficiently collect optimal quantities of milk with the highest possible quality.

Competition in this market is fierce, which is why more and more entrepreneurs are improving their machinery to better meet customer needs. The primary piece of equipment that helps dairy farmers collect milk from cows is the milking machine.

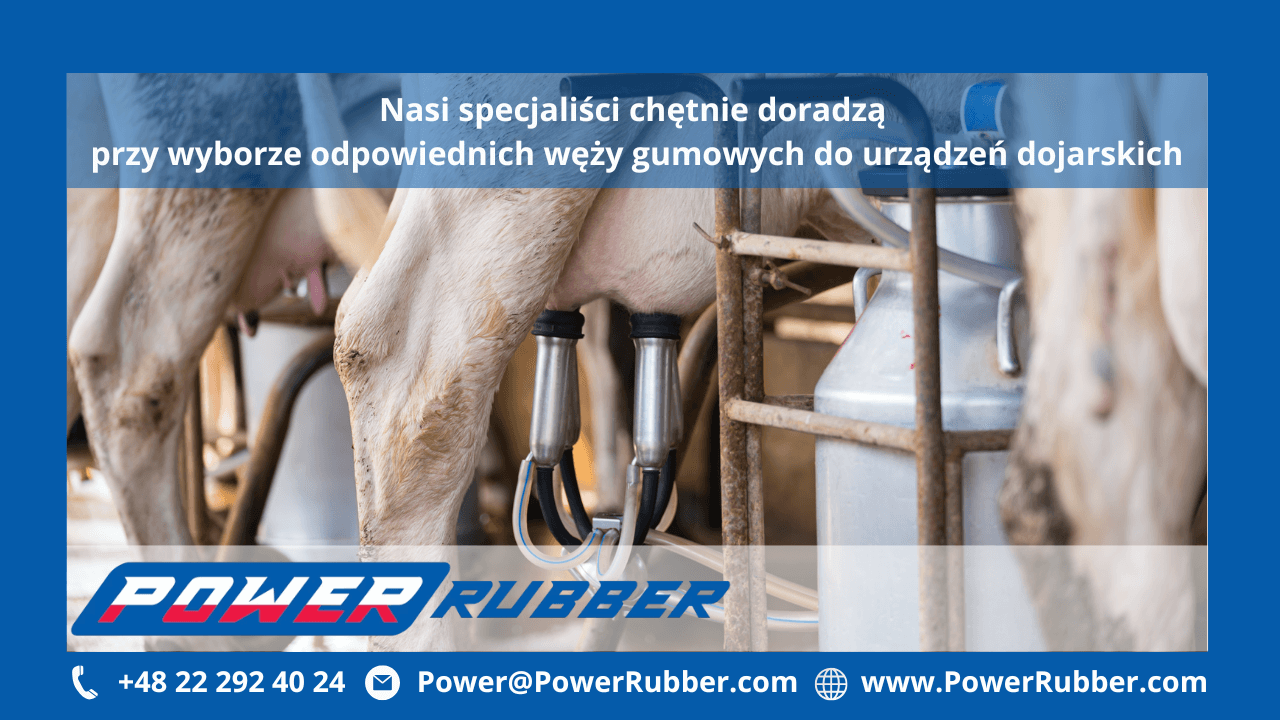

One of its key components is the special rubber hose used first for suction and then for milk ejection. The proper working pressure inside the hose and the imitation of natural milking motions help increase production efficiency with the use of such a hose.

Application of Certified Rubber Hoses in Various Industries

Rubber hoses are a versatile product with many advantages. One of them is their ability to adapt to a wide range of dairy applications. They are designed for suction and pumping of liquids, both food-grade and from other industries. They maintain the integrity of dairy products in milking machines, processing equipment, and tankers, ensuring efficient transport of liquids without contamination. Milk hoses are also widely used in other sectors of the food industry, not just in dairy production.

Silicone hoses are also used for pumping highly concentrated alcohol, up to 96%. Additionally, due to silicone’s resistance to concentrated chemicals, especially inorganic compounds, these hoses can also pump liquids with highly acidic pH, even below 4.6.

The food-contact certification issued by the relevant authority guarantees that silicone hoses or other certified materials will not transfer their odor or taste to the food or liquids transported inside.

Specialized rubber hoses are found in nearly every production facility. They can handle large volumes under pressure, ensuring quick and efficient liquid movement. They can also be used for the transport of primary products in liquid or gas form, depending on the type of hose, or for supplying auxiliary substances, such as draining water.

Milk hoses offer excellent flexibility and properties that make them ideal for handling sensitive products. They are commonly found in chemical and biological laboratories as part of equipment. These types of hoses are manufactured with scientific applications in mind and often meet additional criteria.

Hoses are also widely used in hydraulics, the automotive industry, and various other industries, both heavy and light. Their application is almost limitless as they often form part of more complex machinery.

The material used in hose production is known for its high durability. It is difficult to damage. The flexibility changes with the thickness of the walls, and consequently, the internal diameter of the hose. It also depends on the material used for the particular model. The outer layer affects the flexibility and the final shape of the milking machine’s entire device. This has both advantages and disadvantages. Softer hoses allow for easier and more convenient installation on the teats, which is also less uncomfortable for the cow because they are much lighter. On the other hand, heavier hoses with stiffer (yet always somewhat flexible) walls are much more durable, better resistant to scratches, pulls, tears, and other damages. Such a hose is slightly more difficult to install and may be less comfortable for the cow, but this largely depends on the animal's sensitivity.

How to Properly Choose Milking Hoses?

Milking machines have revolutionized the dairy industry, significantly increasing milk production. The milking hose plays a key role in connecting automatic machines to storage tanks, ensuring a smooth flow of milk. These hoses must meet strict safety standards to maintain proper hygiene without any traces of chemical contamination.

Today, rubber hoses are made from many types of synthetic materials, ensuring various properties. Their common feature is high resistance to external factors such as temperature, UV radiation, and abrasions. These specific features and precise parameters depend on the type of material used to produce the hoses.

The hose used for milk must be extremely durable and resistant to potential mechanical damage. Intense use, as well as varying weather conditions, means that without high-quality production, hoses can quickly wear out or significantly slow down the milk production process.

Hoses are used in the dairy industry not only for milking cows but also in transportation. An important factor is their relatively easy cleaning. At the early stages of production, hoses undergo various rigorous certifications, receiving special certificates that allow safe contact with food. The inner surface of the product is perfectly smooth, which facilitates effective and efficient cleaning, as well as ensuring optimal liquid flow. They can be easily cleaned with cleaning agents or during sterilization to remove milk residues.

Choosing the Right Milking Hose

Each farmer should select a hose that best matches the characteristics of their operation, and also fits the cows they have. Some people prefer strong, flexible hoses because they have limited space and sensitive cows, and soft hoses are more comfortable for the animals. On the other hand, if the hoses are exposed to cold or are at risk of mechanical damage, it is wiser to choose stiffer models, which are more resistant.

Another important but often overlooked issue is the hose length and possible connection of several elements, as well as the working pressure. Although this may seem like a simple and trivial task, it is essential to know how to do it correctly and securely in the case of hoses with different diameters or hose breaks. The best solution, unchanged for many years, is special aluminum connectors and worm drive clamps. The flexibility of silicone or other materials used for the hose ensures proper installation without the risk of creating any gap. An alternative solution is to use expansion sleeves or similar products.

Milk Rubber Hoses Properties

Due to their durability, flexibility, and compliance with food safety standards, milking hoses are typically made from rubber or silicone. High-quality milk hoses can withstand reversible deformations due to mechanical forces. They maintain the continuity of the structure, making them very durable.

The most popular milk hoses are made of transparent silicone or single-color rubber (e.g., black). For special milking machines, flexible plastic hoses are typically used, with the inner layer perfectly smooth. The outer layer usually remains without any embossing or has a subtle texture that may serve anti-slip functions when handling and installing the hose to the milking machine.

Reinforced hoses contain additional spiral wiring inside, which strengthens and reinforces the structure, providing it with a longer lifespan.

Both silicone and multi-type elastomer milk hoses have a high tolerance for temperatures (from -60°C to over +300°C), although manufacturers recommend a working temperature range from -30°C to +70°C.

The milking hose has high resistance to cleaning agents, which are effective and safe for surfaces in contact with food. It does not degrade due to physical cleaning with brushes or special tools for internal disinfection, removing milk residues that may harbor bacteria. As a result, these hoses can be easily washed and disinfected with hot water or steam up to +110°C, although this contact should last no longer than 30 minutes. The pressure inside ensures that contaminants are removed. An alternative cleaning method is rinsing with chemical solutions specifically designed for this purpose.

All rubber materials used in milk hose production are highly flexible. This allows for a lot of freedom in adjusting the hose’s arrangement and installation to the teats and the rest of the mechanical device.

Disadvantages and Advantages of Using Rubber Hoses

Milk transport hoses are integral components of the milking process. They are valued for their durability and resistance to wear. Perhaps their most important feature is the perfectly smooth inner surface, which enables fluid transport without the risk of clogs that could jeopardize the entire production. Clogs quickly develop bacteria and mold, which could then contaminate the rest of the milk in the tanks. Our offered hoses feature structural continuity and high resistance to damage, including the formation of gaps and cracks where fluids might start accumulating, so they do not pose a real threat. In this way, milk or water can flow freely through the milking machine without disruptions during suction or ejection.

Another important advantage of rubber hoses for milking machines is their versatility. Many people appreciate this material for its ease of cleaning. The necessary document for using milk hoses is, of course, certification that allows contact with food. This also requires regular maintenance of sterile and appropriate hygiene for these hoses. Given the current, highly developed and specialized market, this is not difficult. Every farmer can easily find concentrated cleaning chemicals in both online and brick-and-mortar stores that thoroughly clean milking machine hoses, leaving them completely unobstructed. These preparations work much more effectively than just hot water. They remove the fat, which is abundant in fresh milk, ensuring that no infection or mold develops inside the channel, and the outer layer remains undamaged. Manometers make cleaning even easier. The precise measurement controls the working pressure.

The rubber hoses offered on our website come exclusively from reputable manufacturers who ensure the highest quality of both the flexible material and the milk hose production. This guarantees long-term product usability and a durable structure. This eliminates the risk of the formation of micro-cracks inside the hose, which could lead to bacterial growth or complete damage to the mechanism. Thanks to rigorous control already at the production stage, silicone rubber hoses for milking machines can serve for many long years without part replacements. This also allows for significant savings on device renovations and temporary production downtime.

One potential drawback is the improper selection of a milk hose for specific needs and herd characteristics. However, this problem can be resolved by consulting with an experienced seller before making the purchase, who can help choose the best model and rubber material for the hose.

Other Types of Hoses Used in Other Food Industry Sectors

Although the dairy industry has many types of mechanical devices that assist in milking cows, the most popular ones use high-quality flexible hoses made of appropriate materials. These rubber hoses for sucking milk in milking machines have a working pressure of 45 to 55 kPa, so it is essential to ensure they are precisely installed.

Selecting the right machine and compatible hoses can ensure many years of intense work while maintaining satisfactory efficiency and low strain on the cows in the herd. Silicone hoses are just one of the many products commonly used in the dairy sector.

Rubber hoses for transporting substances are made from different types of rubber, and manufacturers offer more and more blends and variations, each with its unique properties. Among them are nitrile rubber hoses, which are resistant to oils (both natural and synthetic), as well as alcohols, diluted acids, and bases.

Another popular material is butadiene-styrene rubber. This material has a very high working temperature. It also has a high resistance to water and ozone. However, it should not be used in contact with gasoline, oil, or any grease.

Silicone products are lightweight and highly resistant to most factors, including extreme weather conditions and high temperatures. They are among the most commonly used hoses.

Milk Hose – Benefits of Using It

Milk hoses are specially designed to safely transport milk from the cow to the milking machine, ensuring that it remains free of contamination. Maintaining cleanliness and quality of milk is crucial in dairy farming and milk processing.

Maintaining cleanliness and milk quality is critical in dairy farming and milk processing, which is why it is essential to equip milking machines with certified rubber hoses for milk transfer (some have a special antibacterial insert). This mechanizes a key and vital task that previously consumed the most resources and human time. Thanks to automatic milking machines and compatible hoses, milk production has become faster, simpler, and enables better milk quality due to improved process control.

The dairy industry already has highly developed technical solutions that help dairy farmers and all related workers perform their duties every day. For their comfort and to maintain their business in excellent condition, it's worth investing in additional equipment that will positively impact the quality and efficiency of work.

Although the materials used to produce these hoses have various properties and permissible technical parameters, they are all resistant to moderate cold. They can be used outdoors, even during freezing winters, without fear of cracking, gaps, or other issues. The hoses come with proper measuring systems and manometers that make work easier, as well as measure the working pressure.

Certified Rubber Hoses - Available in Power Rubber Store

At Power Rubber, we supply hoses for milking machines that ensure reliable and hygienic milk transfer while maintaining safety and the quality of dairy products throughout the production process. Milk hoses are resistant to steam sterilization and standard cleaning agents

Rubber Milking Hoses and Other Useful Tools

We invite you to explore our wide range of products available in our online store. In the dairy industry, it’s also a good idea to invest in rubber anti-slip flooring that will provide proper grip and greater safety in the workplace. Anti-slip mats are much easier to maintain than other traditional floors.

Also worth mentioning are O-rings. These small isolation elements protect machines from excessive wear, prevent parts from rubbing against each other, and reduce noise and vibrations caused by intensively operating equipment.

We encourage you to check out the full range of products. Not only milk hoses but all our assortment comes with recognized high-quality certificates and stringent approvals, enabling, for example, direct contact with food and drinking water.

We will gladly assist you in selecting the right product tailored to your individual needs and specific applications. We offer a diverse selection, so we believe everyone will find something for themselves.

Feel free to contact us by phone at +48 22 292 40 24 or +48 505 16 03 03, by email (Power@PowerRubber.com), or via our contact form.