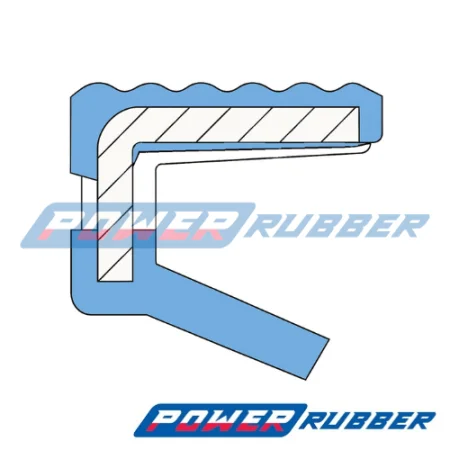

oil seal AO

AO Simmering is a basic radial shaft seal with a dust lip.

The construction of the AO type sealing ring consists of an outer elastomeric shell, a metal sealing insert, and a self-sealing elastomeric ring. It has an additional dust lip that protects against contaminants (dust, dirt, debris, moisture) from entering the interior. The AO rotary shaft seal also prevents leaks of the lubricating medium.

It is used for sealing parts of devices moving in rotary and oscillating motion.

Simmerings are one of the most common seals used in various industries. Therefore, requirements have been standardized, and norms have been introduced regarding dimensions, materials, and types.

Simmering - what is it?

Simmering (Simmering ring) is a technical seal used to prevent leaks of oils and greases from machine components where rotary or oscillating motion is transmitted (mainly shafts). The seal also prevents moisture and contaminants from entering from the outside (mud, dust, dirt).

The seal for rotary shafts consists of a rigid housing and a flexible sealing lip with a spring or without. Its structure may vary depending on the type.

Typical applications

At Power Rubber, radial shaft seals are manufactured from high-quality materials, ensuring proper sealing in a wide range of applications, such as:

- household appliances (dishwashers, washing machines)

- drive units (agricultural machinery, construction machinery)

- heavy industry machinery (wind turbine generators, rolling mills)

- engines (electric motors, internal combustion engines)

- gearboxes (industrial gearboxes)

- hydraulic units

- pumps

Rubber compounds used to manufacture oil seals

To produce sealing rings for rotary shafts of type A and AO, nitrile rubber (NBR), fluorine rubber (FKM/FPM), acrylic rubber (ACM), and silicone rubber (VMQ/MVQ) are most commonly used. Feel free to familiarize yourself with a brief characterization of each material, here it is:

NBR Rubber

The operating temperature range is from -40°C to +100°C. This type of rubber exhibits resistance to engine oils, gear oils, fuel oils, hydraulic fluids, oil-in-water emulsions, greases, as well as water.

ACM Rubber

The operating temperature range is from -20°C to +130°C. Acrylic rubber is compatible when in contact with engine oils, gear oils, and hydraulic fluids.

VMQ/MVQ Rubber

The operating temperature range is from -50°C to +150°C. Silicone rubber is characterized by its resistance to engine oils, gear oils, oil-in-water emulsions, and hydraulic fluids.

FKM/FPM Rubber

The operating temperature range is from -30°C to +180°C. This type of rubber is resistant to engine oils, gear oils, fuel oils, oil-in-water emulsions, hydraulic fluids, as well as synthetic fire-resistant fluids.

Type A and AO seals, which meet the following standards

PN-72/M-86964 – Rubber sealing rings for shafts with a metal stiffening insert. Dimensions. PN-72/M-86965 – Sealing rings for shafts in a metal housing. Dimensions.

PN-88/M-73067 – Sealing rings for rotating shafts according to ISO standards. Nominal dimensions and tolerances.

PN-81/M-86960 – Rubber rings for sealing rotating shafts. Common requirements and tests

At Power Rubber company, we provide simmering rings in compliance with strict quality requirements and standards. Our Simmer rings, among other things: ensure tightness of bearing nodes, prevent leaks of lubricating medium (both during operation and standstill), and protect machine and equipment components from the ingress of various contaminants.

PN-72/M-86964

The standard covers the dimensions of rubber sealing rings for shafts with a stiffening metal insert type A, according to PN-66/M-86960

Below is an example of the designation of the size of a type A Simmer ring according to the PN-72/M-86964 standard:

Sealing ring A 6x22x7 NBR, where:

d (nominal inner diameter of the ring) = 6 mm

D (nominal outer diameter of the ring) = 22 mm

b (ring height/thickness) = 7 mm

NBR – type of material the simmering is made of

PN-72/M-86965

The PN-72/M-86965 standard defines the dimensions of Simmer rings in an external metal housing type B, according to PN-66/M-86960, used for sealing shafts.

Radial shaft seals type B are constructed with one lip reinforced by a metal ring. The outer layer is not covered with elastomer.

Below is an example of the designation of the size of a rubber ring in a metal housing according to the PN-72/M-86975 standard:

Sealing ring B 52x72x10 NBR, where:

d (nominal inner diameter of the ring) = 52 mm

D (nominal outer diameter of the ring) = 72 mm

b (ring height/thickness) = 10 mm

NBR – type of material the Simmer ring is made of

PN-88/M-73067

The PN-88/M-73067 standard covers the nominal dimensions and tolerances of sealing rings for rotating shafts according to ISO (International Organization for Standardization) standards. The International Standardization Organization ISO has introduced unified standards concerning the production of sealing rings for shafts

PN-81/M-86960

The standard covers common requirements and tests for rings with a rubber lip with a metal stiffening insert or in an external metal housing or other construction according to technical documentation. Radial seals, also called Simmerings or Simmer rings, are used for sealing rotating shafts at pressures not exceeding 0.02 MPa. This depends on the material from which the shaft sealing ring is made and the working environment temperature. According to the standard, for shafts with a diameter above 200 mm, recommended rotational speeds and circumferential speeds should be agreed upon between the manufacturer and the recipient.

Need type A and AO simmerings compliant with the above standards? Feel free to contact us.