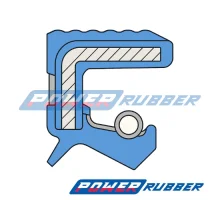

oil seal AOH

Simmering AOH is a rotary shaft seal used in industrial machines and automotive applications. Its purpose is to prevent oil leakage and the entry of contaminants. It features a metal casing, a compression spring, and an additional dust lip that protects against dust and dirt. Made of durable elastomers, they provide resistance to wear and high temperatures, ensuring a long seal life.

How are AOH type oil seals constructed?

Simmering AOH is an advanced rotary shaft sealing system, consisting of several key elements. Its design includes a reinforcing metal skeleton that provides stability and durability. The sealing lip made of elastomer is pressed against the shaft using a spring, ensuring effective protection against oil leakage. Additionally, AOH seals have a dust lip that protects the mechanism from contaminants. Thanks to this construction, they guarantee long-lasting and reliable operation in challenging operating conditions.

What is the purpose of Simmer's AOH rings?

Simmer type AOH rings are rotary shaft seals used in automotive, machinery, and hydraulics industries. Their main purpose is to prevent leaks of oil, grease, and other operational fluids, as well as to protect mechanisms from contaminants. Thanks to the built-in dust lip, they effectively shield against dust and moisture. Their durable construction ensures resistance to high temperatures, pressure, and abrasion, making them a reliable component in demanding working conditions.

Application of AOH simmering

Simmering AOH finds wide application in mechanisms requiring reliable sealing of rotating shafts. They are used in gearboxes, internal combustion engines, hydraulic pumps, and compressors, where they protect against oil leaks and the ingress of contaminants. In automotive industry, they seal crankshafts, camshafts, and gearboxes. In machinery industry, they shield bearings and rotating components from dust and moisture. Thanks to their durable construction, they ensure long service life and trouble-free operation of systems.