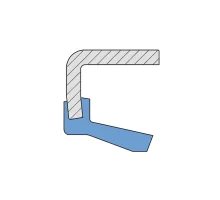

oil seal BO

BO type oil seals are double-lipped seals with a dust lip. They have springs and a metal insert. They are used to seal rotating shafts, effectively preventing oil and grease leaks in industrial machinery and automotive applications. Their design includes a metal frame, an elastomeric sealing lip, and a tension spring, ensuring stability and durability. Thanks to dual protection, BO oil seals perform well in challenging operating conditions, such as gearboxes, pumps, and hydraulic systems.

How are BO type oil seals constructed?

BO type simmerings are two-lip seals for rotating shafts, which provide effective protection against oil leaks and contamination ingress. They consist of a metal reinforcement frame, an elastomeric sealing lip, and a compression spring that ensures constant pressure on the shaft. Additionally, they have a dust lip that protects the mechanism from dust, dirt, and moisture. Thanks to their robust construction, BO type simmerings perform well in demanding operating conditions, such as engines, gearboxes, and hydraulic pumps.

What is the purpose of BO simmering rings?

BO type simmering are used to seal rotary shafts in conditions requiring protection against both oil leaks and contamination. Thanks to two sealing lips, including an additional dust lip, they effectively protect mechanisms from dust, moisture, and dirt. They are used in mechanical gears, hydraulic pumps, compressors, and internal combustion engines, where durability and resistance to intense operation are crucial. Their robust construction ensures long life and reliability in challenging working conditions.

Application of BO type simmer rings

Simmer rings of the BO type are used in systems requiring effective sealing of rotating shafts and protection against contaminants. Thanks to the two sealing lips, including a dust lip, they are used in internal combustion engines to protect crankshafts and timing gears from oil leaks. In mechanical transmissions and gearboxes, they prevent dirt and moisture from entering. They are also used in hydraulic pumps, compressors, and lubrication systems, ensuring long life and reliable operation in harsh operating conditions.