Waterjet cutting

Waterjet

Water jet cutting in Warsaw

and surrounding areas with POWER Rubber

Waterjet cutting is a cutting service that involves using a high-pressure stream of water. Depending on the material and thickness to be cut, cutting can be done with just water or with the addition of abrasives such as Garnet - garnet sand (mineral) offered as abrasive cutting.

The pressure in the systems varies and depends mainly on:

- Manufacturer of the cutting equipment

- Age of the machine

- Software used - Materials being cut

- Technology applied

- Nozzle and other components used

Number of hours worked These elements mentioned above also affect the accuracy of the finished product for this cutting service.

The standard tolerance for waterjet cutting is 0.01 mm or 0.1 mm. Compared to other processing methods such as laser cutting in Warsaw, this allows for maintaining high quality. Tolerance also affects the completion time, especially visible for thicker materials like tiles and plastics.

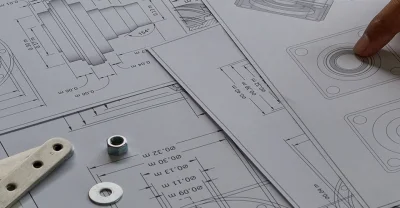

Thanks to the use of professional AutoCAD software, waterjet cutting allows for obtaining various shapes:

- Straight

- Bending

- Recurring

- Semicircular

- Elliptical

- Other possible shapes

It is also worth noting that this method is one of the most environmentally friendly in the market of services. The main argument confirming the environmentally friendly approach is the absence of harmful fumes, which can occur when using CO2 laser cutting.

Additionally, waterjet cutting service has three main advantages:

- Does not deform the material being cut

- Does not cause micro-cracks

- Preserves edge smoothness

Depending on the cutting machine used, these are key elements for choosing this professional method. Depending on the supplied material, this method is defined as a safe cutting method, which results in reducing the possibility of the cut material catching fire.

Like any machine, the waterjet also has disadvantages, although these disadvantages relate to production nuisances. Waterjet cutting and its most commonly cited disadvantages are:

- high noise level during cutting

- low cutting speed ( this is due to the possibility of cutting thick parts)

- high power consumption

- large H2O intake

- relatively expensive cutting material - garnet

In summary, the possibilities of high-pressure cutting outweigh the minor effects that make it possible to achieve such high technical parameters of cutting. Our waterjet cutting is a service that allows high tolerances, even to 0.01mm. We offer in addition to other services such as laser cutting, or production of finished products, preparation of projects and consulting to provide professional services.

Waterjet cutting is widely used. This is due to the minimization of tool losses and high adaptability to materials. Thus, the main materials cut with waterjet - waterjet are:

- tiles

- gres

- glass (including tempered glass)

- stainless steel

- carbon steel

- other types of steel

- plastics

- ceramics

- aluminum

- granite

- stones

- marble

- conglomerate

- rubbers

- gaskets

- wood

- wood-like boards

- laminates

- concrete

- sheets

- other non-ferrous metals and alloys

- non-ferrous metals, including aluminum

As excerpted by the Specialists, the range of materials is very wide. Thus, we confirm that the technology used is widely used to process materials in various industries.

- metallurgical

- construction

- advertising

- design

- stonemasonry

- glazing

- automotive

- pharmacy

- heavy industry

- ceramics

- automotive

- manufacturing

- repair

- service

Indication of industries, further emphasizes the importance of the various elements of high-pressure waterjet cutting. This is mainly due to the high quality and the possibility of repeatability. This highlights how difficult processes can be without waterjet cutting.

Referring to the location waterjet Warsaw service, thanks to our location on the borders of the capital, makes it possible to offer niche rates for a given processing, especially for materials such as:

- plastics

- tiles

- other materials

Professional machining is a type of service available using a combination of cutting technology and water, which is why it is called: waterjet cutting. Check out all the cutting services at POWER Rubber.

POWER Rubber has its facility in Pruszkow, at 5A Domaniewska Street in Mazowieckie Voivodeship. The location is close to the Pruszkow S8 /A2 exit. Access, depending on the district, is from 5 minutes to 20 minutes without traffic jams. This location allows to reduce costs, which translates into a cheaper offer for waterjet service in Warsaw. Check: waterjet price in POWER Rubber !

Feel free to contact us for a quote for the cities of Warsaw, Pruszków, Piaseczno and surrounding areas. It is advisable to send us a project to illustrate the shapes to be cut for the offered waterjet service.

+48 533 78 78 63

power|powerrubber.com| |power|powerrubber.com

Frequently asked questions

Learn about the main industries using waterjet cutting method

- metallurgical

- construction

- advertising

- design

- stonemasonry

- glazing

- automotive

- pharmacy

- heavy industry

- automotive

- manufacturing

- repair

- service

Indication of industries, further underscores the importance of individual components cutting with high-pressure water. This is mainly due to the high quality and the possibility of repeatability. This underscores how difficult processes can be without waterjet cutting.

On what depends the pressure occurring in the systems

What does the cutting service depend on?

Learn about the main industries using waterjet cutting method

On what depends the pressure occurring in the systems

What does the cutting service depend on?

Production of custom rubber products

Tailored solutions for your industry

At POWER Rubber, we specialize in the production of custom rubber components. With a modern machine park and advanced technology, we can fulfill almost any project - from prototypes to mass production. Regardless of the industry you operate in, we offer comprehensive support in design, compound selection, molding, and cutting of components according to your specifications.

What can we produce for you?

We manufacture both simple and technologically advanced components using materials like solid rubber, micro rubber, foam rubber, SBR, NBR, EPDM, CR, silicones (including FDA-approved), and technical rubbers with reinforcing additives. Our products include, but are not limited to:

-

technical seals,

-

rubber washers,

-

bumpers and shock absorbers,

-

custom-cut rubber mats,

-

specialized parts for machinery, production lines, and conveyor systems.

Design flexibility and full process control

Throughout our collaboration, we provide full technical support and advice. We can work based on client documentation or create a project from scratch following guidelines, sketches, or patterns. We select the appropriate hardness (from 30 to 90°ShA), structure, thickness, and physicochemical properties of the material in line with requirements for wear resistance, chemicals, temperatures, or weather conditions.

Technologies that provide an advantage

Our machine park includes:

-

modern vulcanizing presses,

-

CNC plotters and water jet cutting devices,

-

quality control systems and element measurement,

-

a laboratory for analyzing composition and testing final compounds.

This enables us to guarantee high precision and repeatability even in large production volumes.

Short lead times and production scalability

We understand the pace of the current market - that's why we ensure fast order fulfillment, even for prototyping projects, short runs, or urgent orders. Our production lines are fully scalable - we can start from one piece and scale up to production of thousands of components monthly.

Choose a manufacturer who understands your needs

POWER Rubber is not just a contractor - we are a technological partner who thinks strategically and cares about every detail. With our individual approach, experience, and precision, we can deliver exactly what your company needs - regardless of the industry.

Looking for a manufacturer who will execute your project with the highest care?

Contact us and see what we can create together.

Contact Form