ESD antistatic rubber mats

Antistatic rubber mats - properties

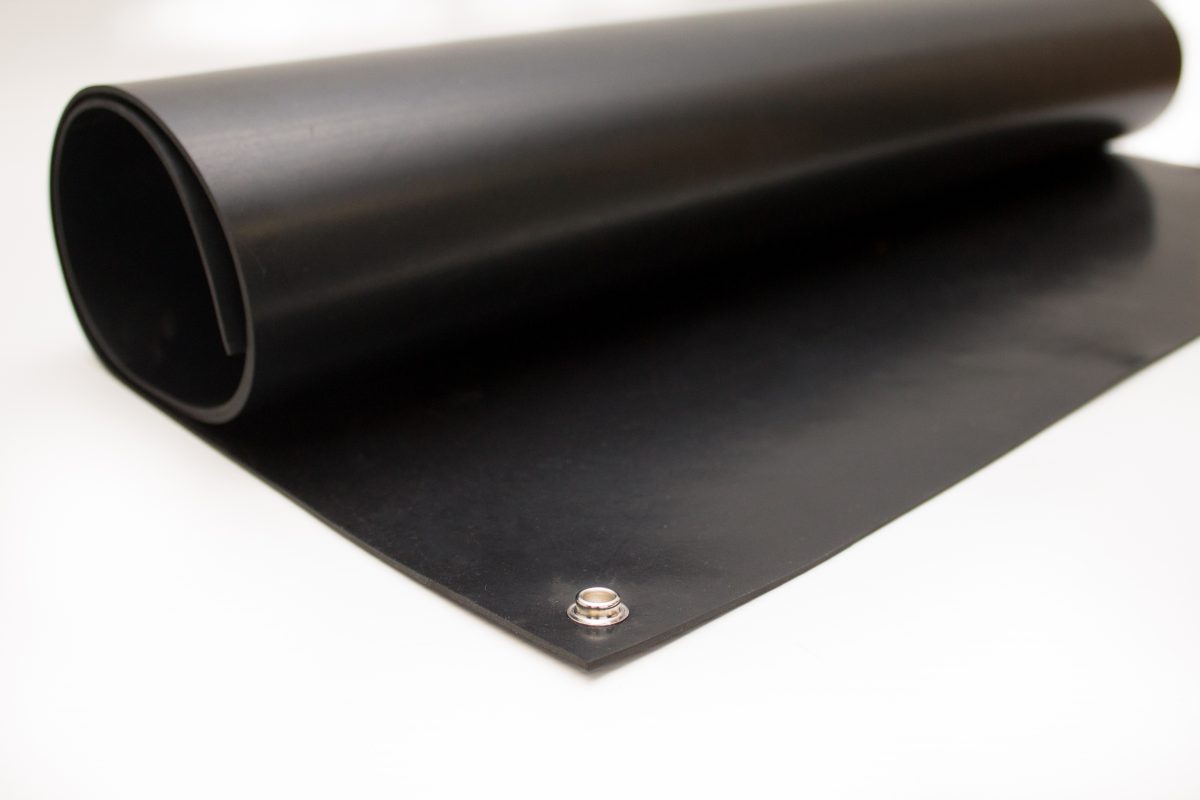

Thanks to the properties of rubber sleepers on the substrates, people and equipment are protected from accidents. In addition, they improve the conditions of the workplace. Antistatic mats are made of high-quality rubber compound. SBR and NBR rubbers are used, which have high mechanical resistance, so mats protect floors from damage, e.g. scratches or permanent dirt. Rubber mats have a very useful non-slip property that protects people standing on the mat from tipping over and injury. Due to their high strength, mats can be used in a wide temperature range, i.e. from -10 st. Celsius to 70 degrees. degrees. The thickness and dimensions of the mat depend on its type and purpose. Carpets of a different size are used on the floor, and others on countertops. Some manufacturers offer products in rolls, sheets of standard dimensions or allow you to place an order for a product of individual dimensions, as specified by the customer. ESD antistatic mats can consist of two layers. This model of mat on the top side is made of a mixture of SBR/NBR gums and nitrile. The substrate, on the other hand, is made of EPDM foam. As a surface finish, a corrugated sheet is used to prevent easy slipping. In addition, chamfered edges reduce the risk of tripping over the mat. Due to the materials used, the upper layer has increased resistance to oils and petroleum-based substances.

Use of rubber mats

ESD antistatic rubber mats are used m.in. in plants where there is a risk that magnetic charge may damage manufactured objects or equipment used. Antistatic mats are durable, so it is possible to use them intensively. They are resistant to abrasion and dents. For this reason, they are often used in the wider industry, also because of their good resistance to water, oils and chemicals. ESD mats, designed for laying on the floor or on the countertop, are easy to install, just lay them on a flat surface, do not require sticking or nailing to the ground. In addition, they are equipped with a male latch, which allows the connection of a grounding wire. Buy ESD antistatic mats here

Buy ESD antistatic mats here Antistatic mats – the most important advantages

Work in the industrial sector is often associated with dangerous conditions that require special safeguards. It is up to them to live and health of employees. Such protection measures are antistatic products, m.in. ESD antistatic mats. They protect against the effects of electrostatic discharges, which can cause losses with their possible harmful effects. Electrostatic discharges are created by ordinary activities such as rubbing materials or walking, when the sole of the shoes is torn off the ground. A product such as ESD rubber mats protects against short circuits, burning or degradation of the performance of electronic devices and components. The use of antistatic mats on workstations can effectively eliminate the impact of electrostatic discharges.