Rubber Density

What is rubber density?

Rubber density refers to the ratio of a rubber material’s mass to its volume. It is expressed using the formula ρ = m/V and is a critical value for evaluating material performance, particularly in sealing and industrial applications.

Which units are used to express rubber density?

The two most common units are kilograms per cubic metre (kg/m³) and grams per cubic centimetre (g/cm³). To convert kg/m³ to g/cm³, divide by 1000. For example, 1300 kg/m³ equals 1.3 g/cm³.

How to convert between units?

To convert from kg/m³ to g/cm³, divide by 1000. To go from g/cm³ to kg/m³, multiply by 1000. Knowing how to convert units helps engineers and technicians select the right rubber material.

What is the typical density of rubber types?

NBR rubber typically has a density between 1.4 and 1.5 g/cm³. FKM (Viton®) can reach up to 2.0 g/cm³. SBR and natural rubber range from 1.1 to 1.6 g/cm³. Butadiene rubber (BR) is lighter, around 0.95 g/cm³. EPDM rubber is about 1.4 to 1.5 g/cm³. Rubber granules, often used in flooring or playgrounds, have a density ranging from 0.2 to 1.15 g/cm³.

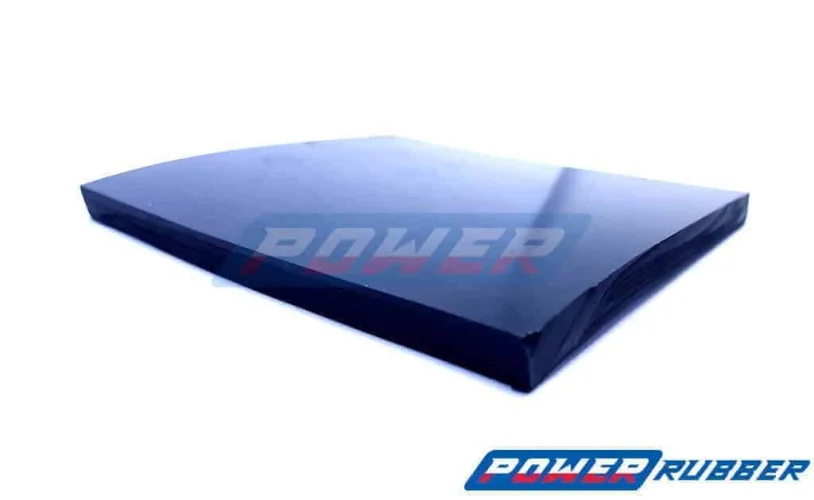

What kinds of rubber materials are available?

There are solid rubber products, foam rubber, and granulate-based materials. Each has its own performance characteristics in terms of flexibility, compression, and thermal resistance.

How does Shore hardness relate to density?

The Shore A hardness often correlates with the density of the rubber. The higher the Shore rating, the denser and more rigid the material. Typical values range from 40 to 90 Shore A, depending on application.

What does POWER Rubber offer?

Our product range includes O-rings, shaft seals, rubber sheets, foam materials, profiles and bespoke industrial rubber solutions. All materials are selected based on specific density and performance criteria.