The purpose of the fair is to promote, sell and build direct relations with potential contractors. For this reason, it is necessary to properly care for the floor so that the presented exhibition looks impeccable. The floor for the fair should be made of high-quality materials and with the utmost care for every smallest detail, so that the entire stand has an appropriate design. An important element when creating floors is taking care of their simple system, which will facilitate quick assembly at the stand. Well-chosen floors will add the right character and atmosphere for all kinds of events.

Choosing the right floor in terms of the materials used

The materials we use to finish the floors differ not only in appearance, but also in properties. When choosing the right floor, it is worth paying attention to whether it will be used outdoors or indoors. Some materials are more resistant to external factors and others less so they can be damaged more easily. You should be aware of the activities that will take place while using the floors, namely: people movement, walking or moving objects. These actions have a destructive effect on the surface, therefore, in order to counteract it, materials should be selected in such a way that they are resistant to dents, squeezing, bending or scratching. The floors for the stands should be selected individually, as each surface transmits sounds or heat in a different way. The manufacturer also made sure that the finishing structures were modern, thanks to which they will look great.

Benefits of raised floors

- easy assembly and disassembly of floor elements

- allows for the exhibition arrangement of event stands

- allows the use of leds that will give a unique look

- obtaining the necessary space under the floor to perform the installations necessary for functioning

- any arrangement of floor panels

- full control of the surface under the floor and the underlying installations

- using environmentally friendly materials

Construction of raised floors

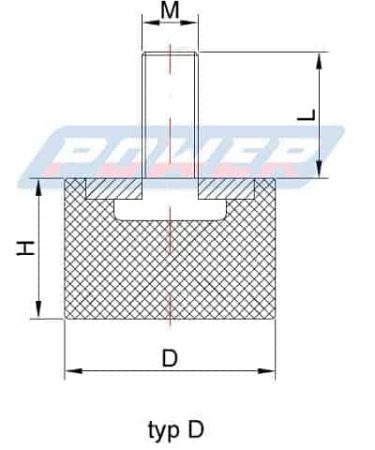

More and more often, multi-level surfaces are created that allow you to arrange the interior to be as functional as possible. The raised floor is not only applicable at trade fairs, but also this floor system works well in other rooms, e.g. in apartments or offices. Most raised floors are located on galvanized steel posts. At the top, there is a post head, which is adapted to the installation of stiffening crossbars. Connecting the head with the foot thanks to a latch or a joint allows you to adjust the height of raising the floors. The posts are spaced at a distance of 60 × 60 cm, while with a higher load, additional posts should be placed in the line of the edge.

Power Rubber raised floors

The raised floor is the most frequently chosen product on the market. Their use is an excellent solution wherever you need to lay out electrical, technical, alarm, computer, fire or climate installations so that they are not visible. It will be perfect for offices, technical rooms or electrical switchboards. It is also an important element of cultural events, which is designed to complement the stands for various types of events so that they look perfect. There are 2 types of raised floors from octanorm.

Octaclasic raised floor

Octaclasic is lined with wooden panels which give the stands an elegant look. The height is only adjustable after assembly. The maximum load is 5000 kg / m2 and its point load is 1500 kg / m2. This type of floor is highly resistant to water and moisture, which makes it an ideal solution for outdoor events. The surface they are covered with is rough, which makes it easier to arrange the equipment safely, and also gives the possibility of placing an additional lining.

Octaeco raised floor

Octaeco is the second type of Power Rubber flooring. Unlike octaclasic, its surface is smooth and made of ecological materials, mainly recycled. It is valued for its quick assembly and disassembly, such a system definitely facilitates the work. Its height is 43 mm, however, it depends on the foot, which can be adjusted as needed and can reach a height of up to 100 mm. Octaceo has a much greater strength, as much as 20 tons / m2, and its maximum point load is 7.14 tons.

Good to remember

When entering our website Power Rubber, it is worth remembering to accept cookies, thanks to them you have full access to the materials on it.